About TheDieCasting

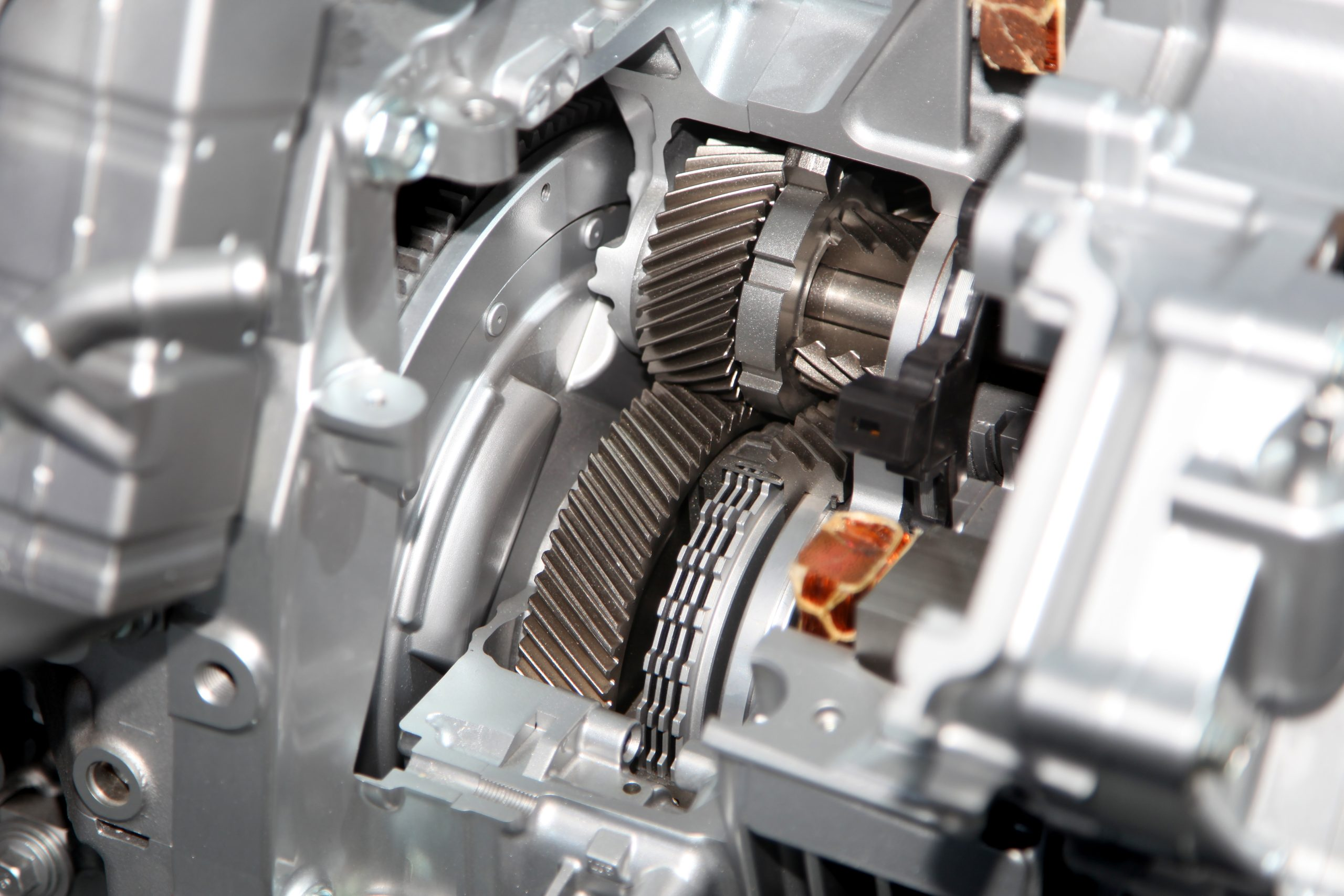

As a leading China die casting manufacturer, we specialize in high-pressure die casting services for aluminum, zinc, and magnesium alloys. With over two decades of experience, we deliver precision-engineered die casting parts to clients across automotive, aerospace, electronics, and industrial equipment sectors.

Our mission is to provide reliable, cost-effective, and high-quality die casting solutions with fast lead times and exceptional customer service. We combine advanced technology with strict quality control to ensure every component meets international standards.

- IATF 16949 Certified Manufacturing

- In-House Die Casting Mold Production

- CNC Machining Tolerance: ±0.01mm

- Full Surface Finishing Capabilities