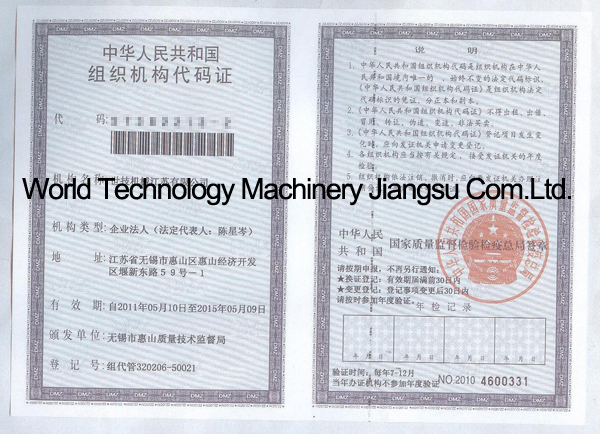

About World Technology Machinery

World Technology Machinery Jiangsu Co., Ltd. is a leading manufacturer and supplier of high-precision tube production machinery. With years of engineering excellence, we specialize in designing and building complete production lines for stainless steel clad tube mills, steel tube & pipe making machines.

Our product range includes high frequency welded tube mills with diameters from 8 mm to 610 mm, square & rectangular tube mills, spiral welded pipe mills, slitting lines, and a full suite of auxiliary equipment for seamless steel pipe manufacturing.