About Unice Mold

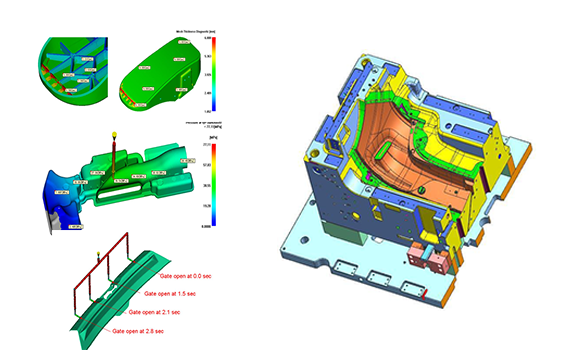

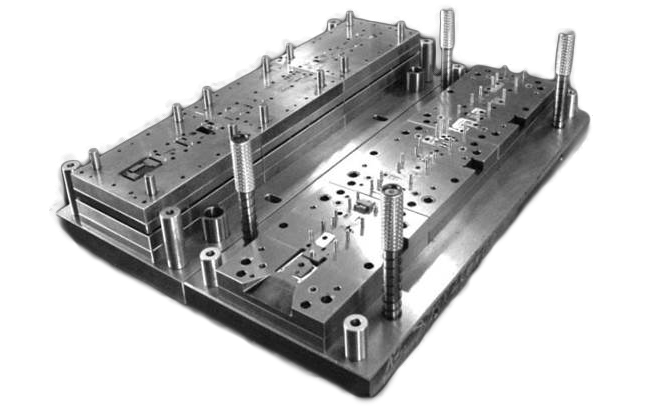

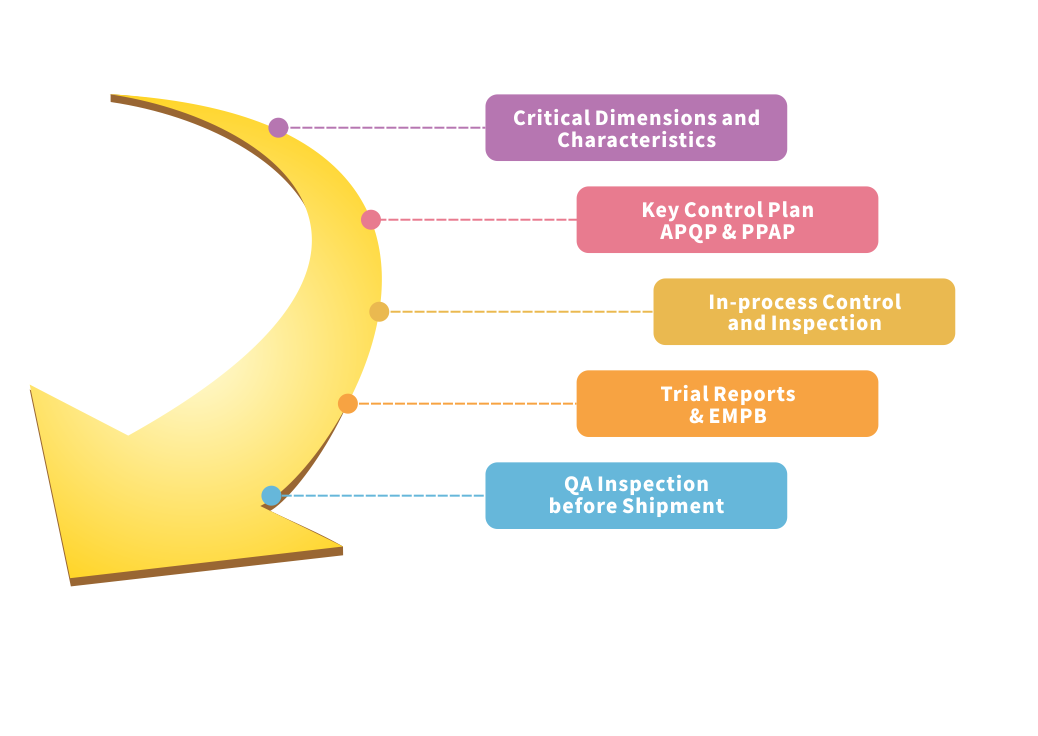

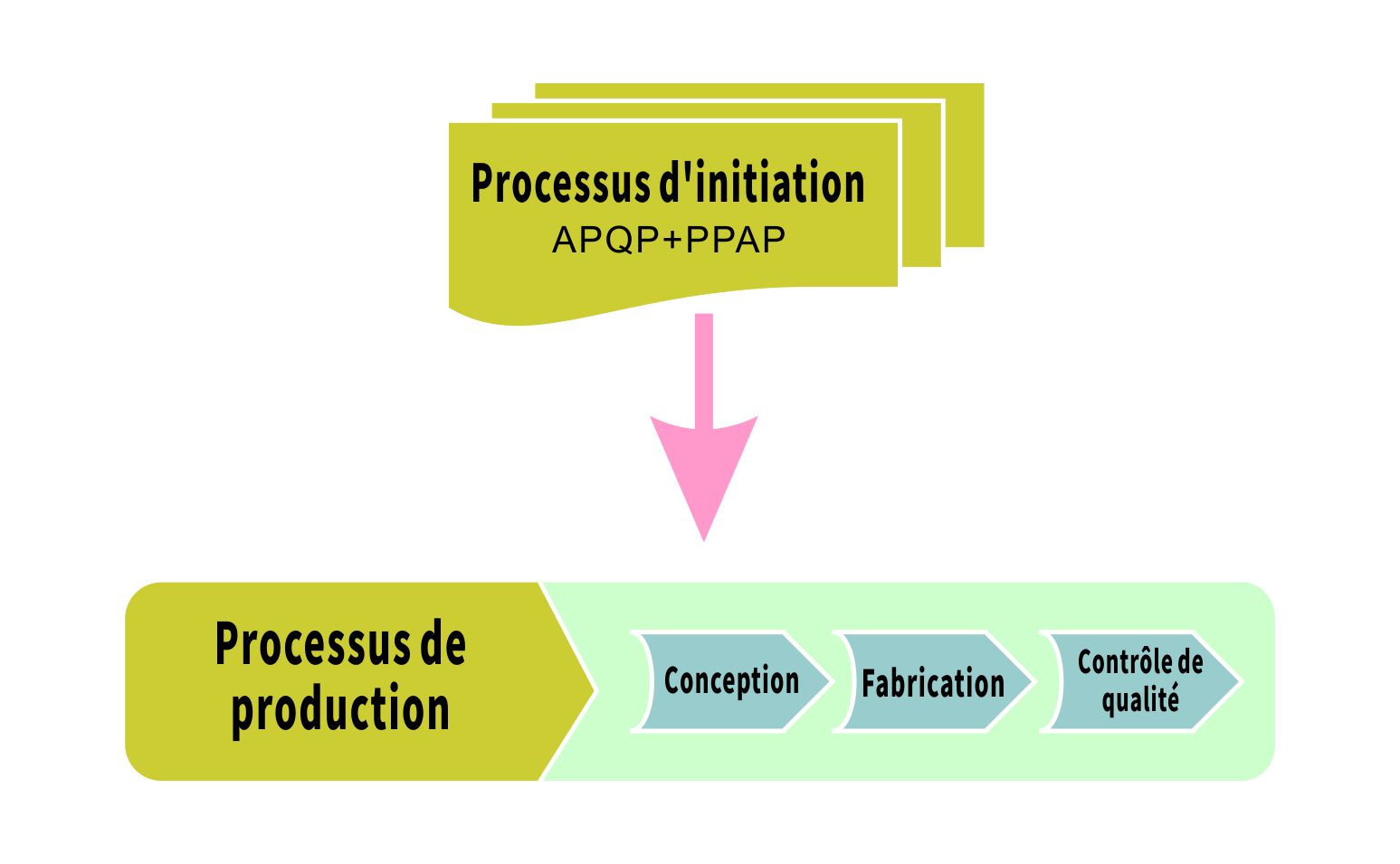

Unice Mold Industrial Co., Ltd is a trusted manufacturer specializing in injection mold manufacturing, custom plastic injection molding, stamping molds, precision machined parts, and prototype parts.

Our company places strong emphasis on personnel training and technological advancement. Over the years, we have built a high-quality, efficient, and quality-oriented management and technical service team dedicated to helping customers optimize product structure, develop optimal molding solutions, and reduce production costs.

Following our vision of becoming refined, stronger, and bigger, we have evolved into an industry leader, earning recognition from renowned domestic and international brands.