Trusted Since 2006

Hangzhou Fuyang UVING Office Equipment Co., Ltd. has been a leading manufacturer of paper processing machinery since 2006. Originally exporting under the Wenyuan brand, we launched the UVING brand in 2019 to strengthen our international presence.

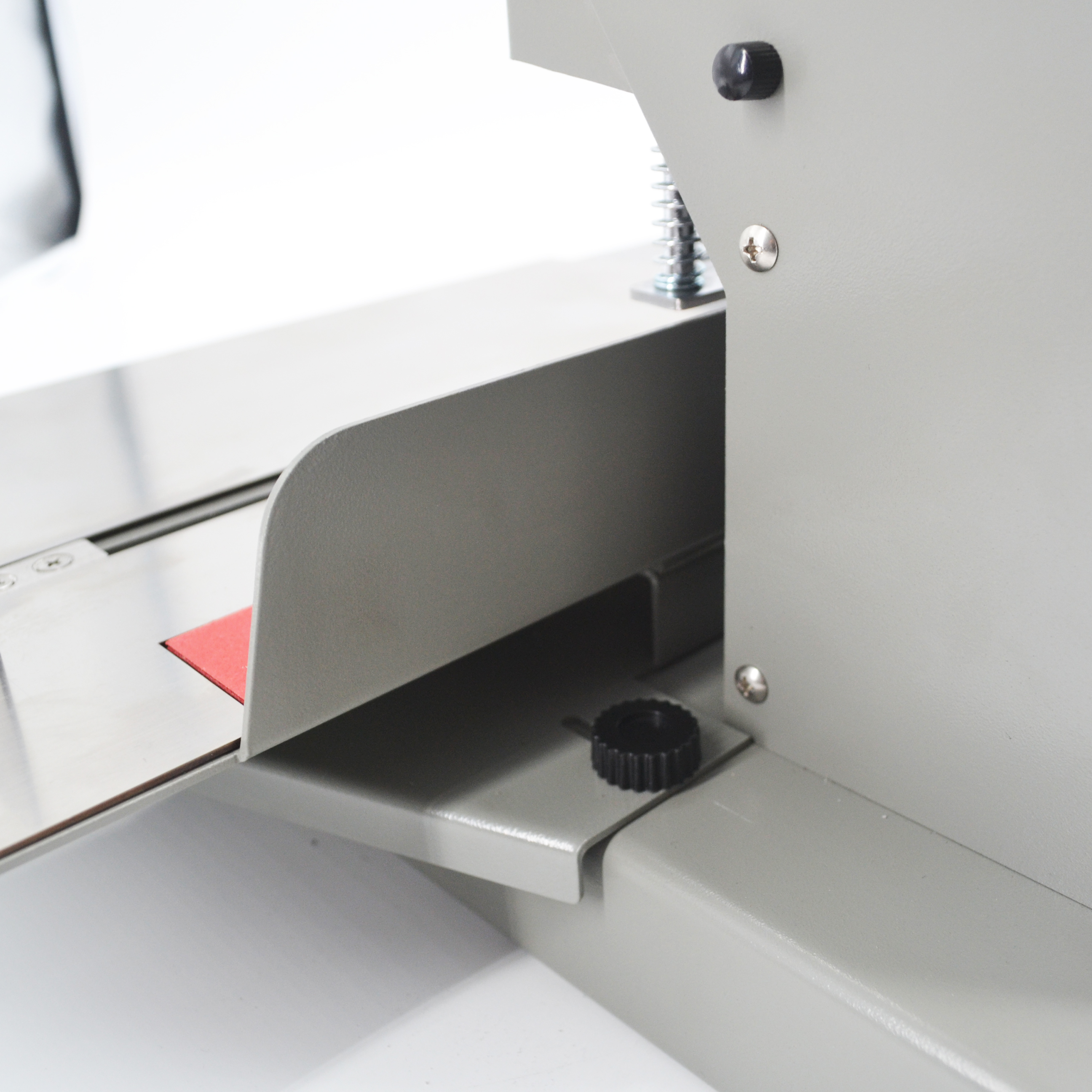

We specialize in post-press equipment including paper drills, creasing machines, cutting systems, and binding solutions. Our products are engineered for durability, precision, and ease of use—trusted by printing companies, educational institutions, and government agencies worldwide.

- 18+ Years of Industry Experience

- Exporting to Over 100 Countries

- ISO-Certified Manufacturing

- Dedicated R&D and Support Team