About WEI LEI MOULD

Shanghai Weilei Mould Technology Co., Ltd. was established in 2011 and is located in Kunshan City, Jiangsu Province — just 40 km from Hongqiao International Airport, offering convenient transportation access.

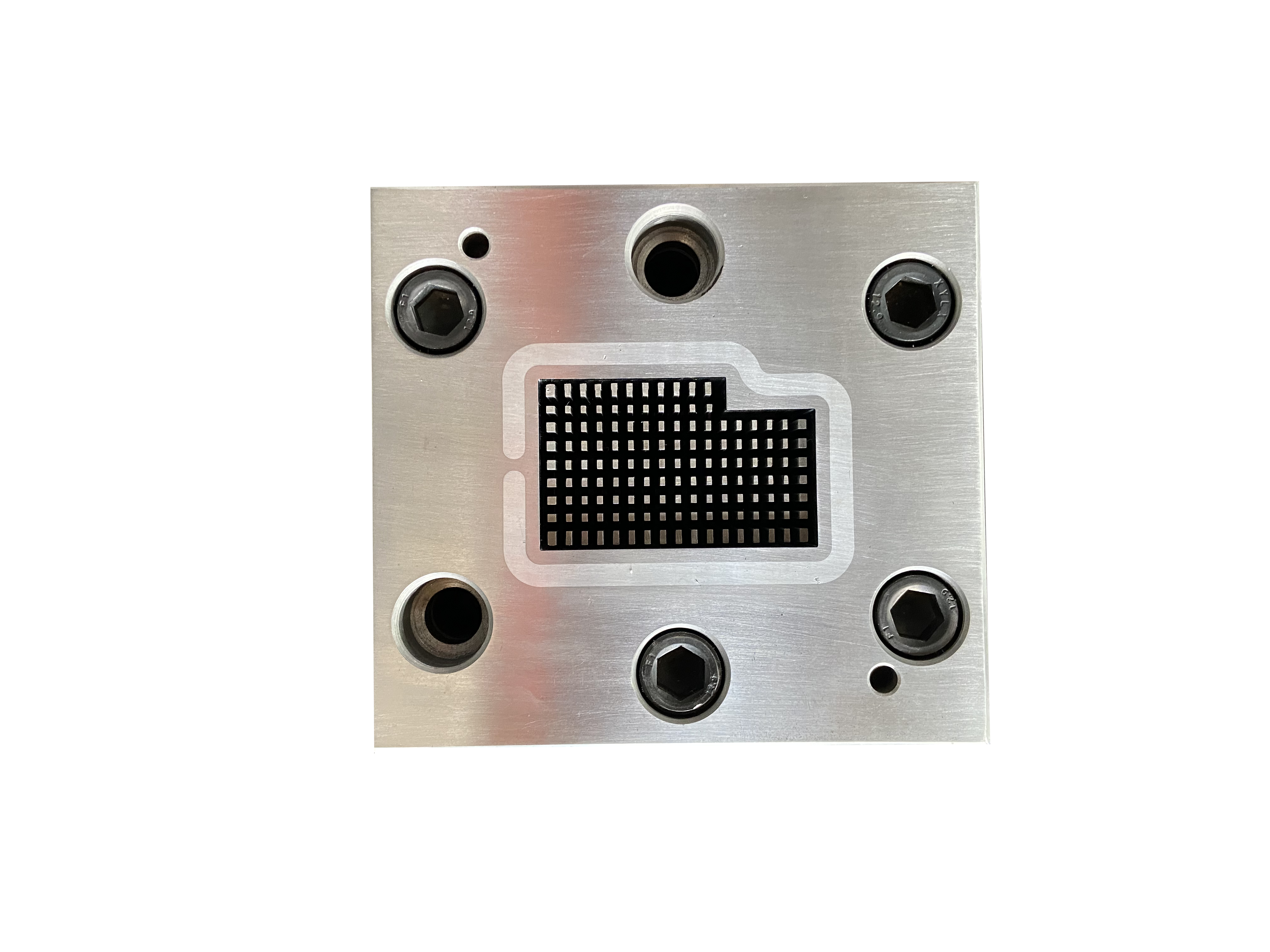

We are a professional manufacturing enterprise specializing in the development, design, machining, and manufacturing of plate and profile moulds. Our expertise extends to after-sales service and technical tracking support for all our clients globally.