About Worldwide Industrial Machinery

A legacy of innovation and precision engineering spanning over eight decades.

Professional

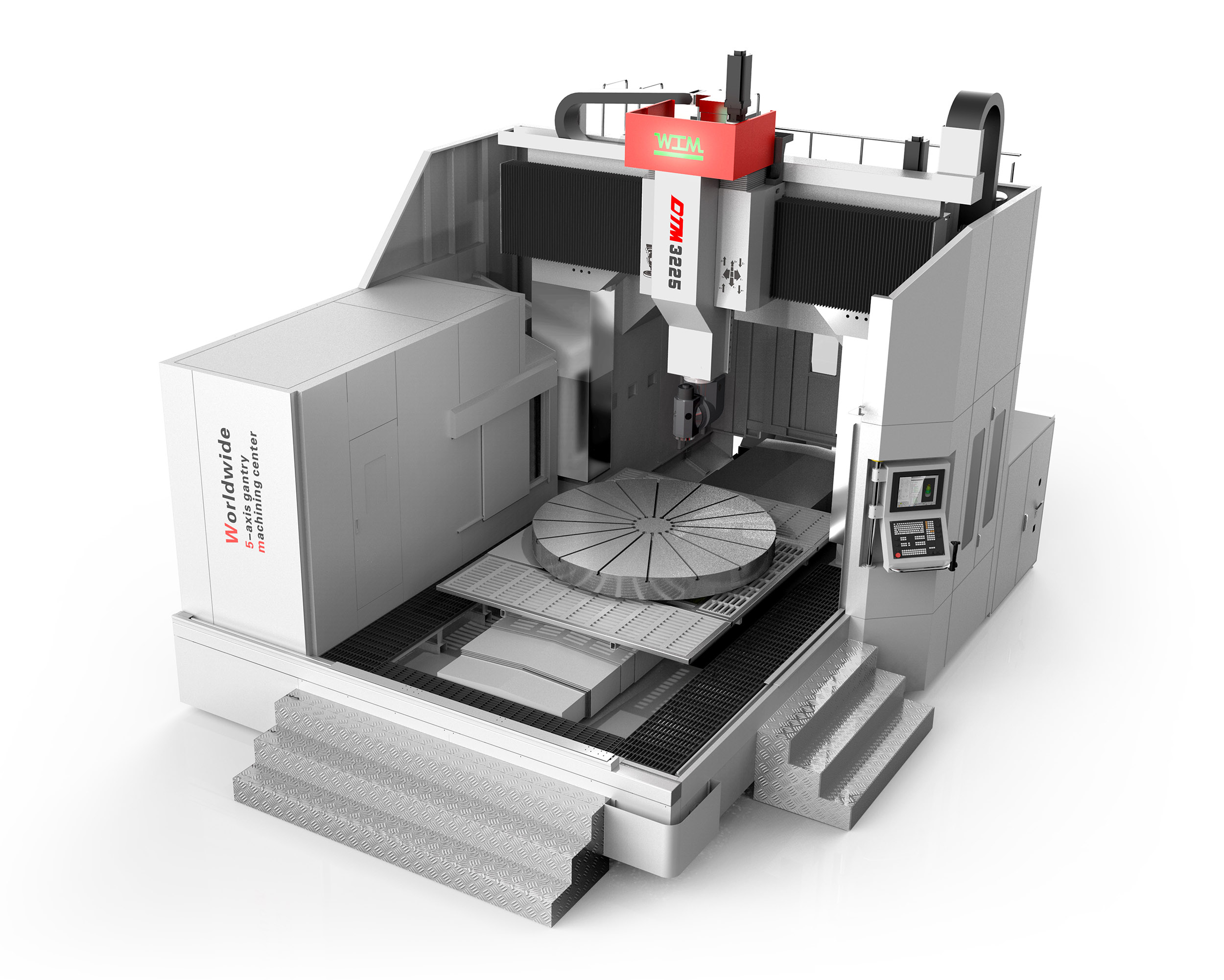

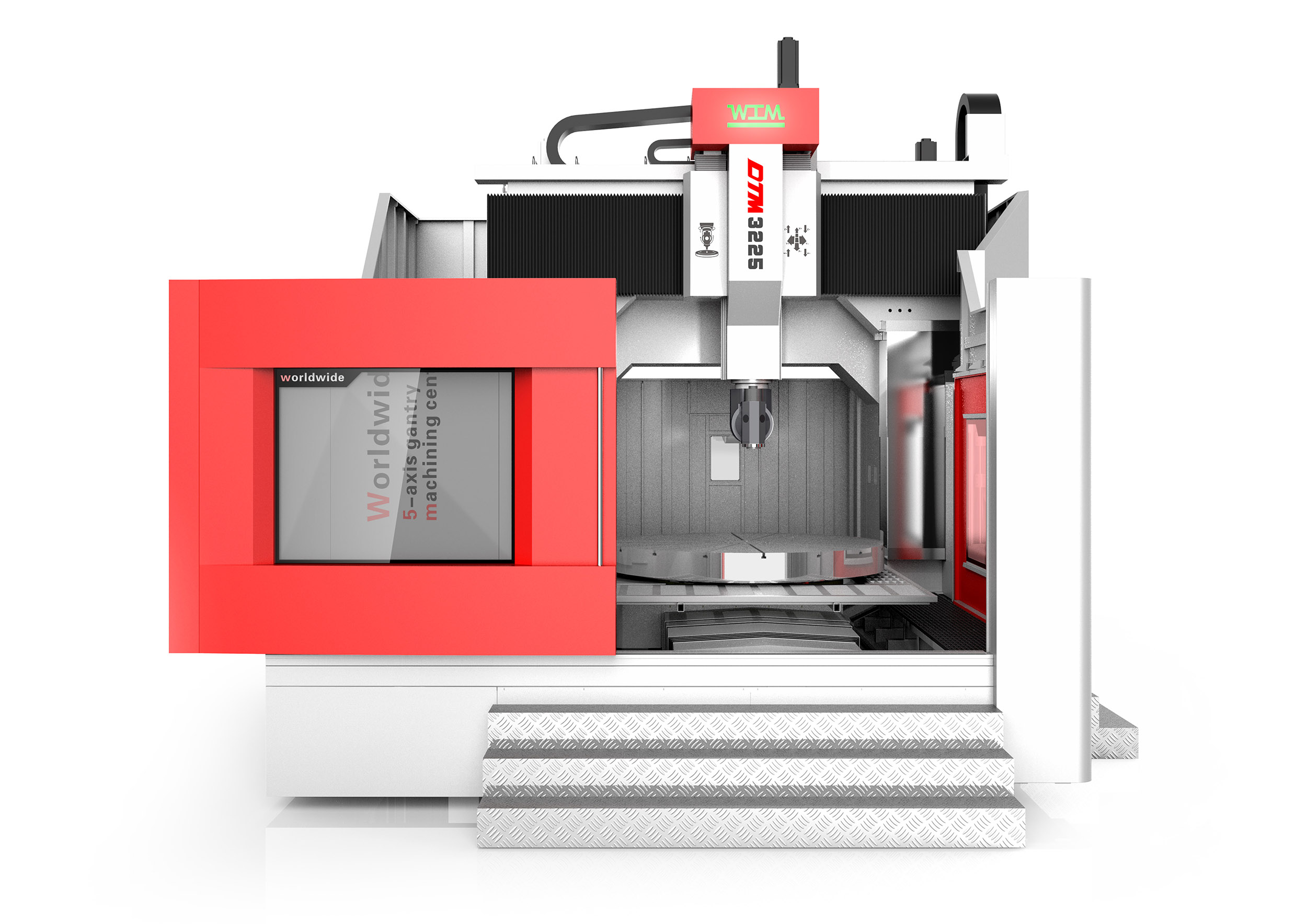

With 80 years of craft heritage, WIM has specialized in the design and manufacture of CNC machines for mold making.

Innovational

Specializing in comprehensive solutions for large mold machining for nearly 40 years.

Competitive

Not only a machinery builder, but also a user. Sharing 40 years of mold base & mold manufacturing experience.

Our Legacy

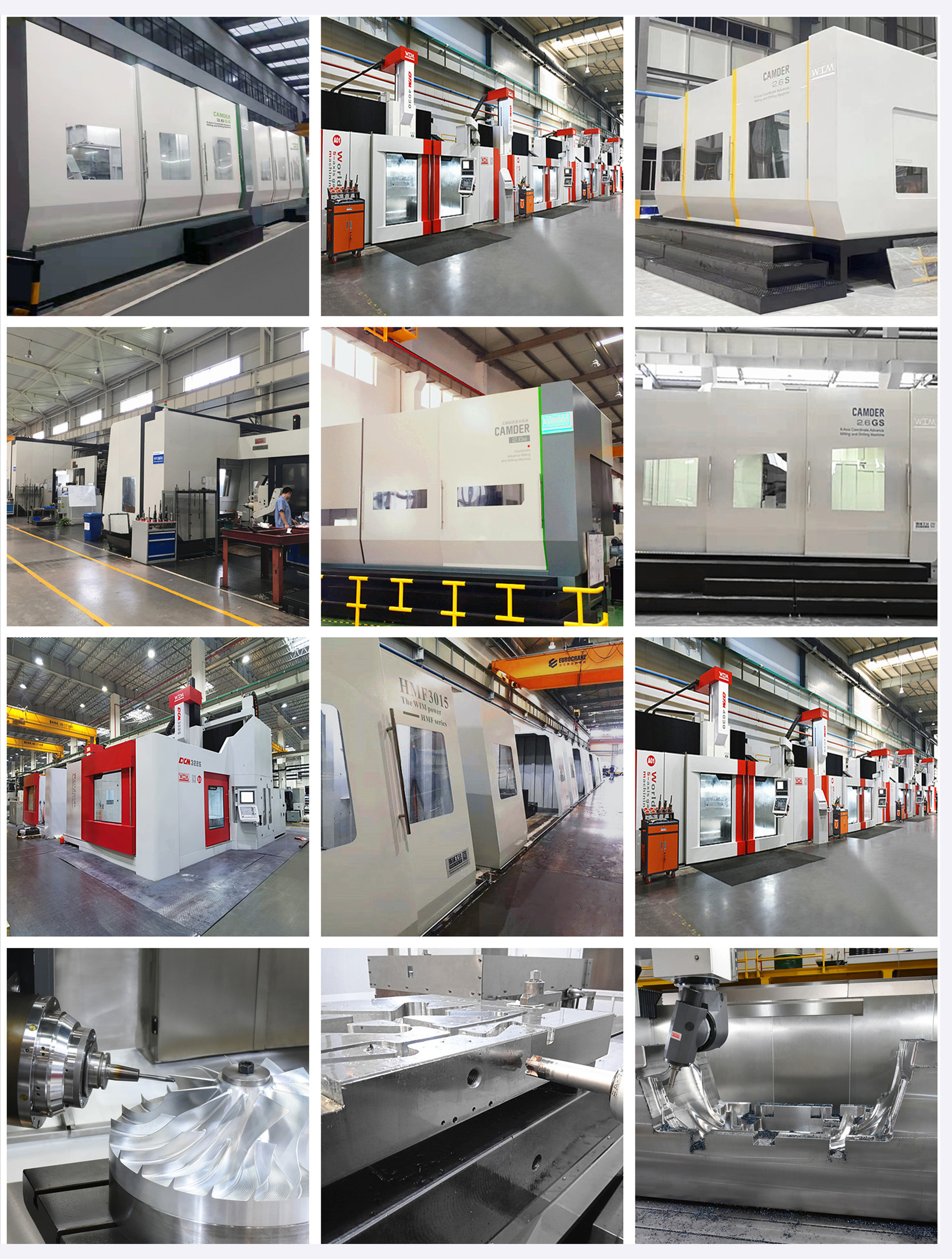

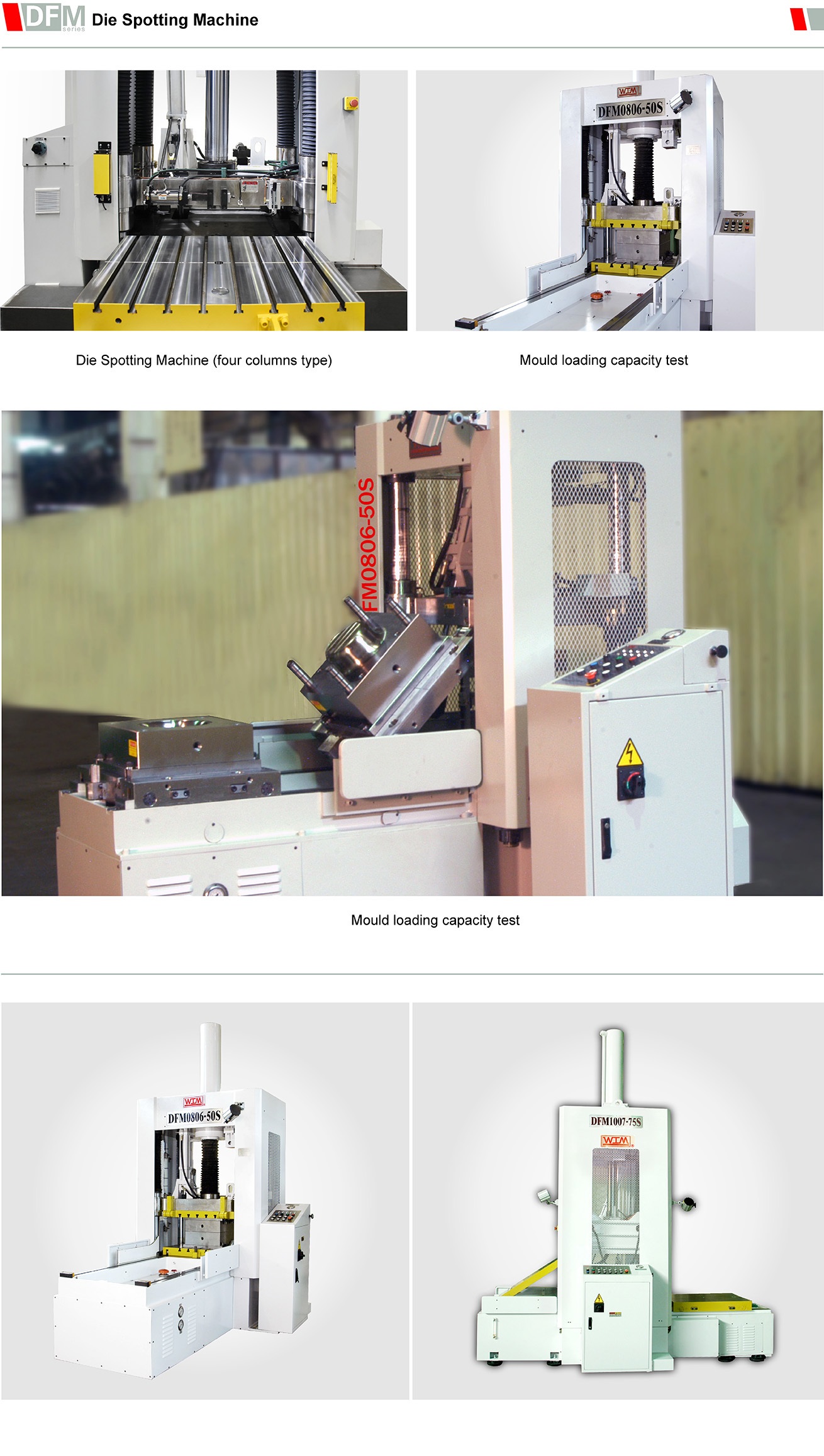

Worldwide Industrial Machinery Ltd. is a professional machining center manufacturer that specializes in deep hole drilling machines. We developed the first 6-Axis Coordinate Advanced Drilling and Milling Machine in Asia, conquering the difficulty of compound angle machining of injection molds with high efficiency and high precision.

The 6-axis CAMDER series was patented in China on April 30, 2009, and has evolved into its fourth generation—offering unmatched accuracy, quality, and user-friendliness for complex applications in automotive, aerospace, and medical industries.