About Wintrustek

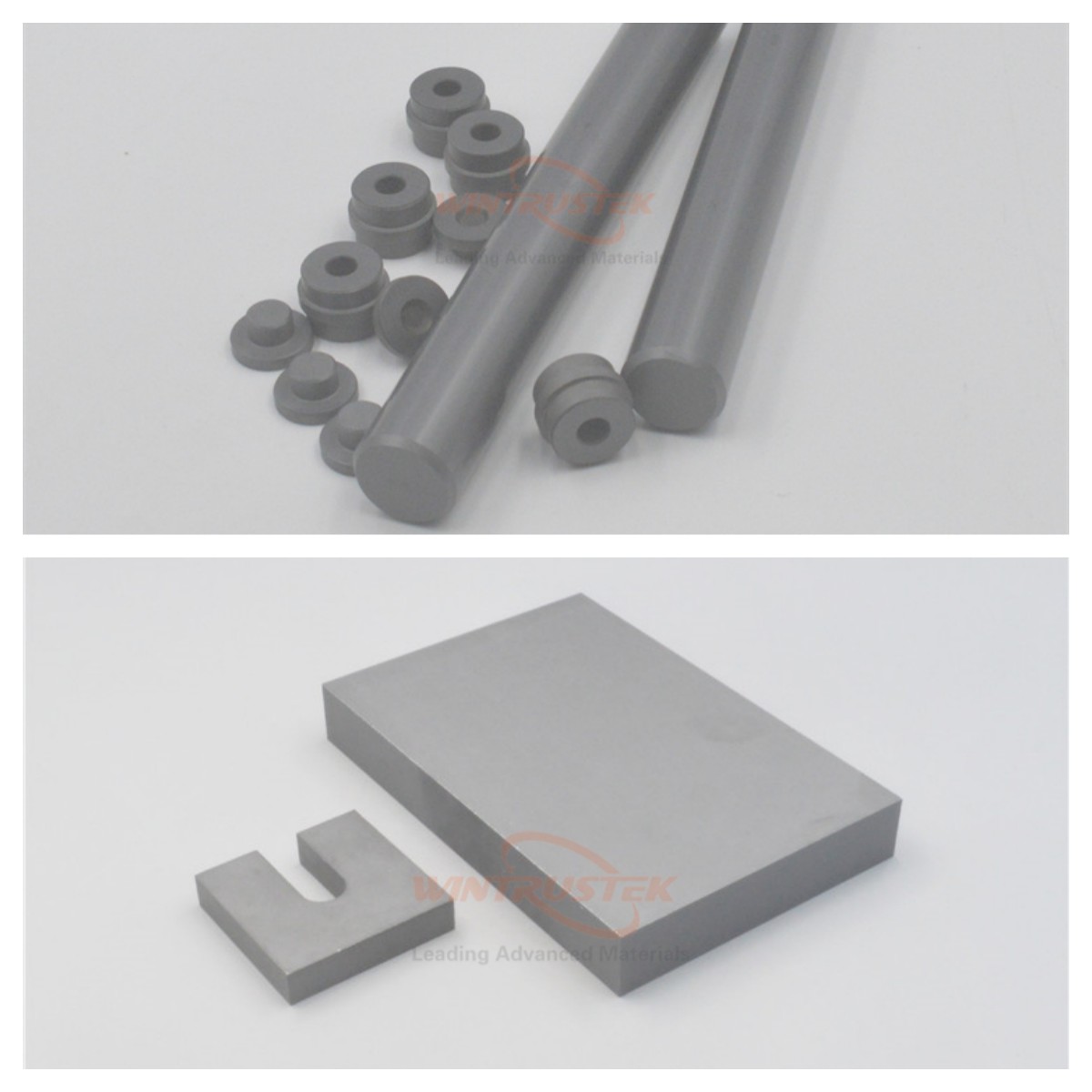

Xiamen Wintrustek Advanced Materials Co., Ltd. has been a leading manufacturer specializing in technical ceramics since 2014. Over the years, we have been committed to research, development, production, and marketing by providing a wide range of advanced ceramic solutions for industries that require outstanding material performance to overcome extreme working conditions.

Your business relies on processes that are efficient and consistent. Our ceramic manufacturing capabilities allow you to concentrate more on your products and worry less about multiple vendors. Clients choose to cooperate with us based on our leading material technology, professionalism, and commitment to the industries we serve.