Trusted Manufacturer of Industrial Wire Mesh

WireClothChina is a leading manufacturer and exporter of high-quality stainless steel wire mesh, woven filters, sintered elements, and custom metal screens. With years of experience in precision wire cloth manufacturing, we serve global clients in petrochemical, pharmaceutical, food processing, and engineering industries.

Our advanced production capabilities include laser cutting, sintering, pleating, and custom weaving to meet exact specifications. We are committed to delivering durable, corrosion-resistant, and high-flow filtration solutions.

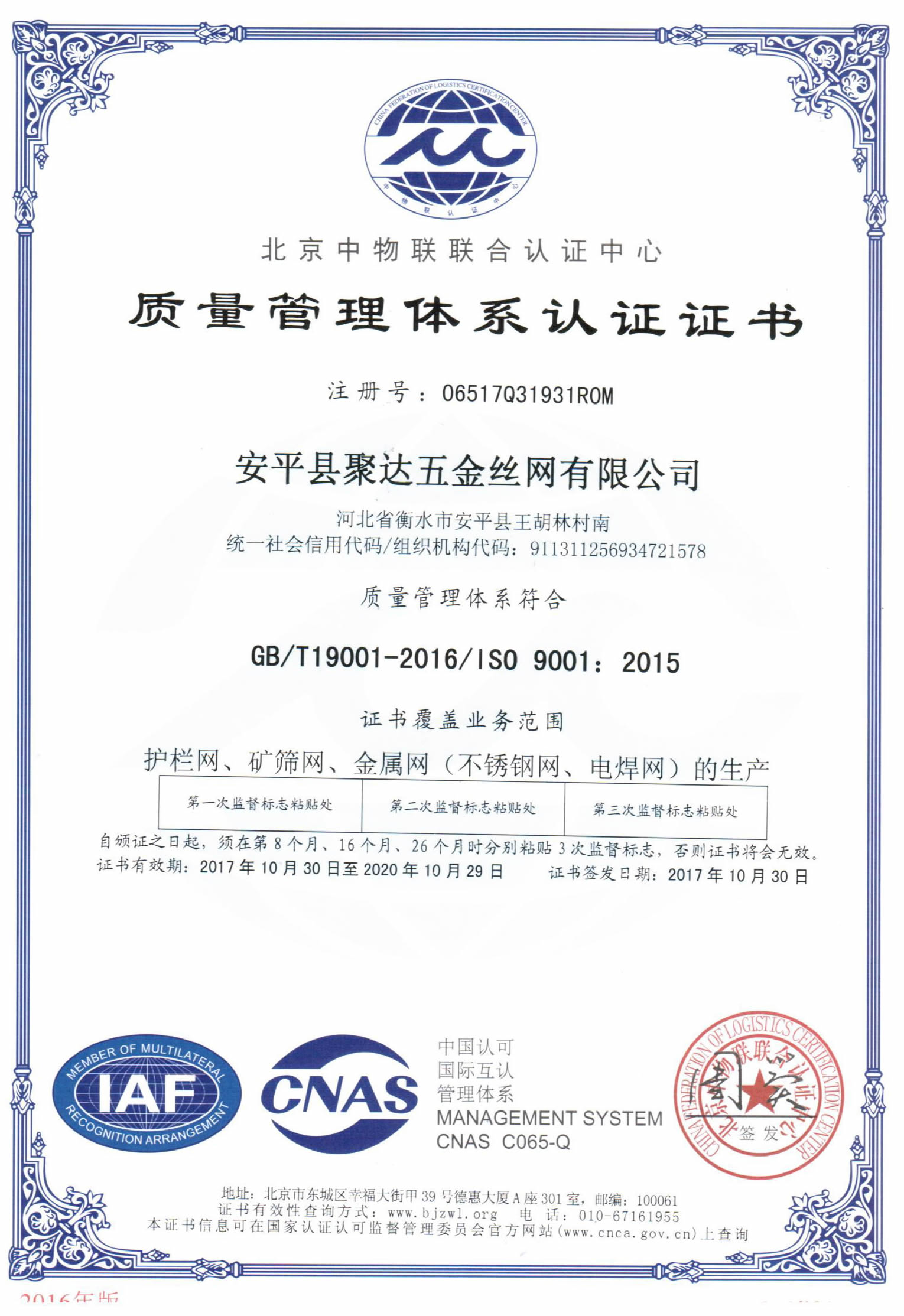

- ISO 9001 Certified Manufacturing

- Custom Design & Fabrication

- Global Export Experience

- Fast Turnaround & OEM Support

9001