YDZY Tech

YDZY Tech

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

YDZY Tech

YDZY Tech

CNC Precision Parts, Die Casting, Injection Molds & Automated Equipment — engineered with micron-level accuracy for global industries.

Far East Tech, operating under YDZY Tech, was founded in 2014 and is headquartered in Bao'an District, Shenzhen, Guangdong. We are an integrated large-scale manufacturing enterprise combining R&D, manufacturing, sales, assembly, and after-sales service.

Our precision parts, molds, automation machinery, and assemblies serve industries including machine equipment, automation, automotive, electronics, medical, semiconductor, and new energy. We work with world-renowned enterprises, including Fortune 500 companies.

As a national high-tech enterprise, we prioritize technological R&D, product quality, and continuous innovation. Our advanced design, processing, and project management services are supported by Industry 4.0 standards and a full ERP system.

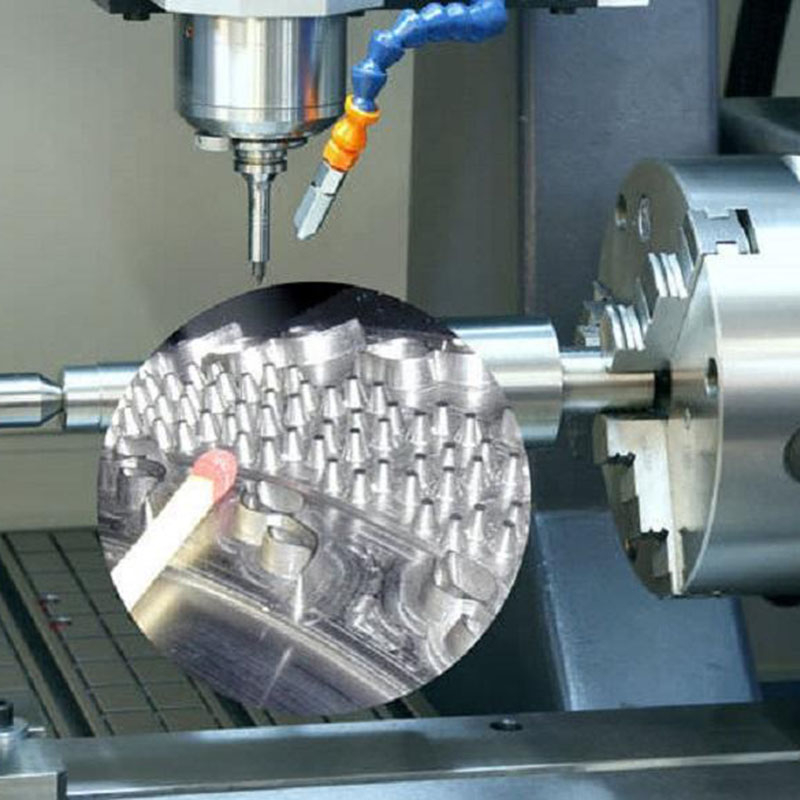

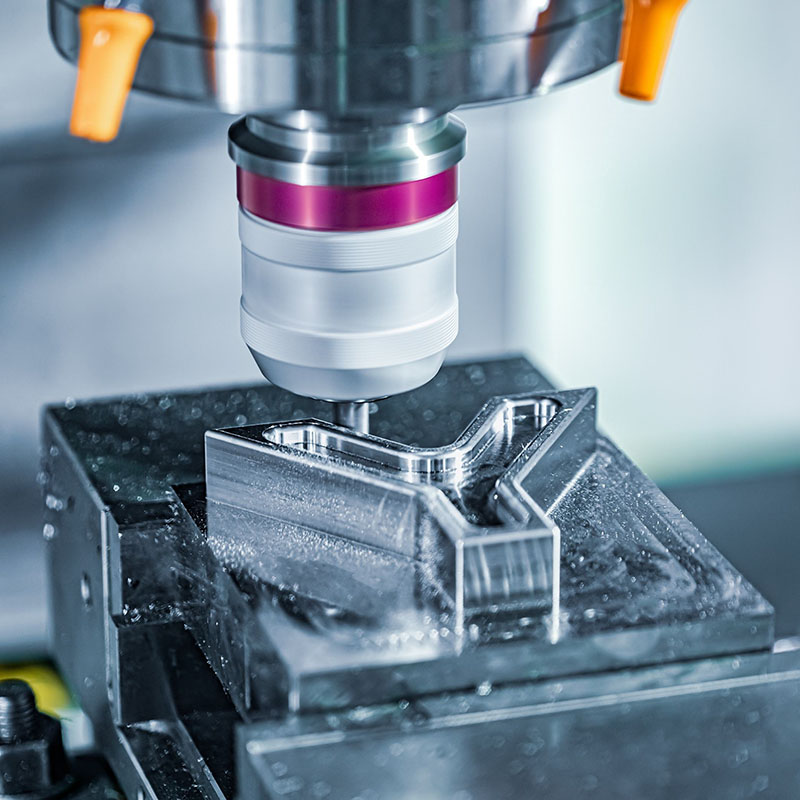

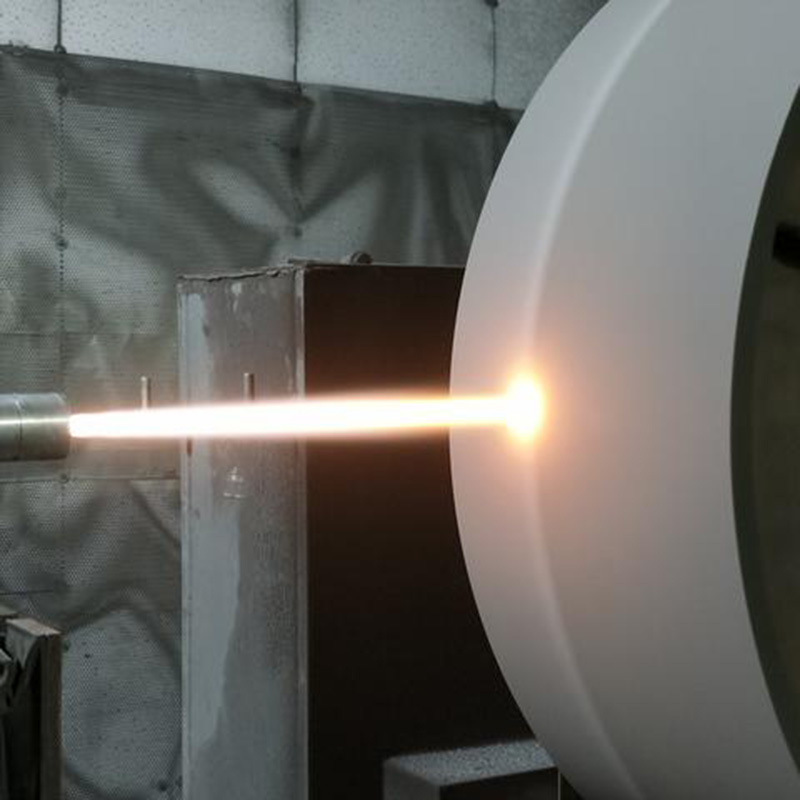

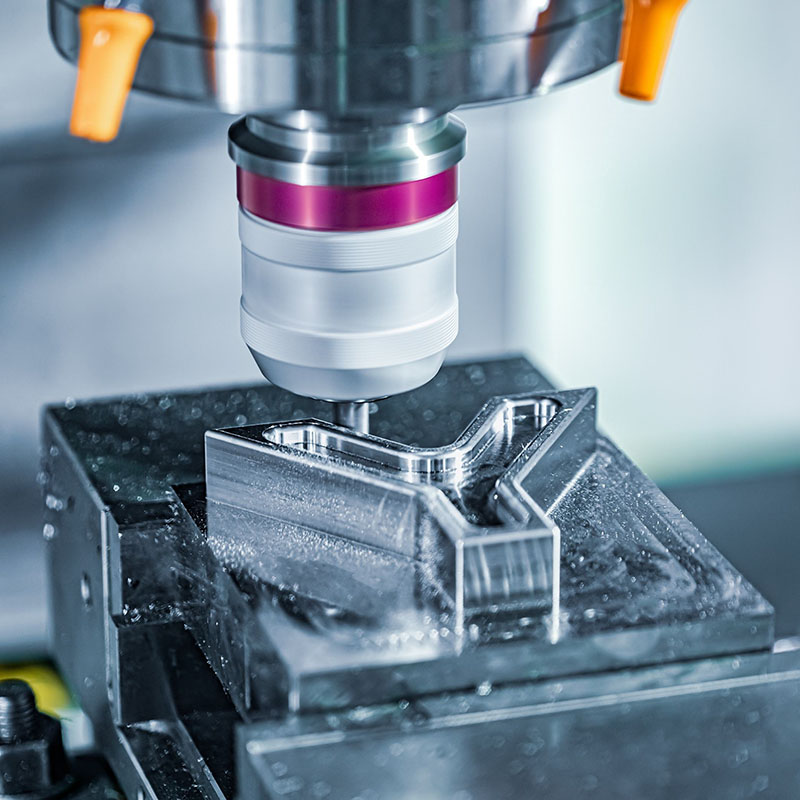

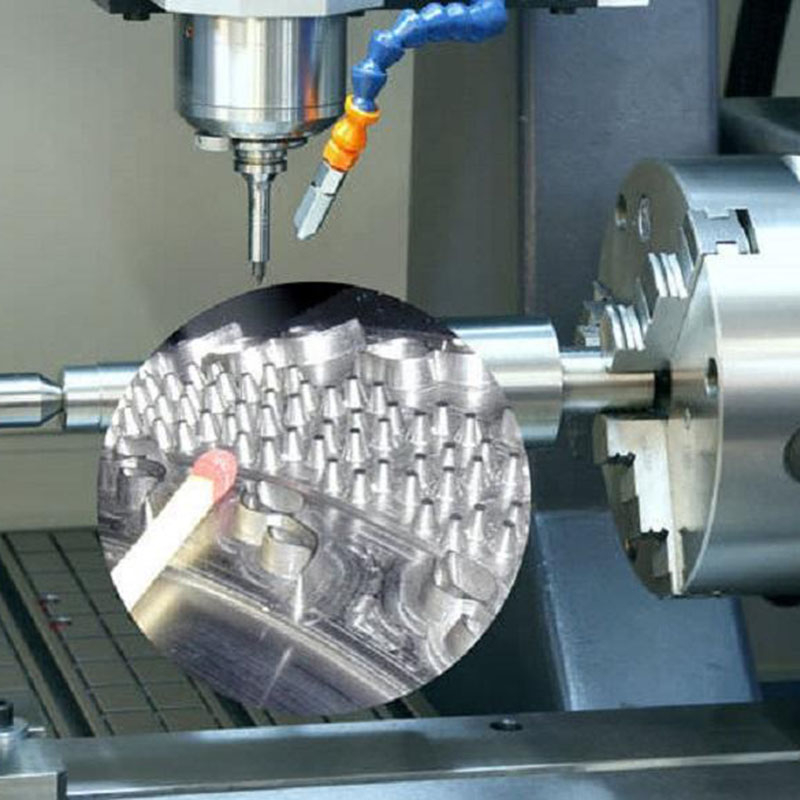

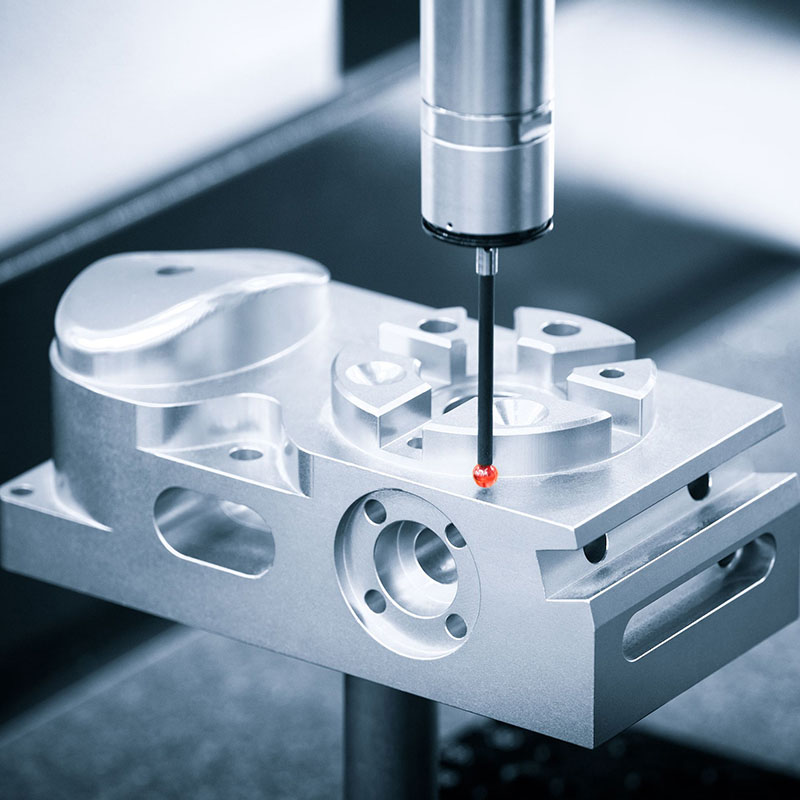

High-precision CNC machining for complex components with tolerances down to ±0.01mm. Ideal for aluminum, stainless steel, and alloy parts.

Learn More →Complete sheet metal services including cutting, bending, welding, and surface finishing for enclosures, brackets, and structural parts.

Learn More →Expert milling, turning, and grinding of die-cast parts for automotive, industrial, and consumer applications.

Learn More →Custom mold components machined to exact specifications with high surface integrity and dimensional accuracy.

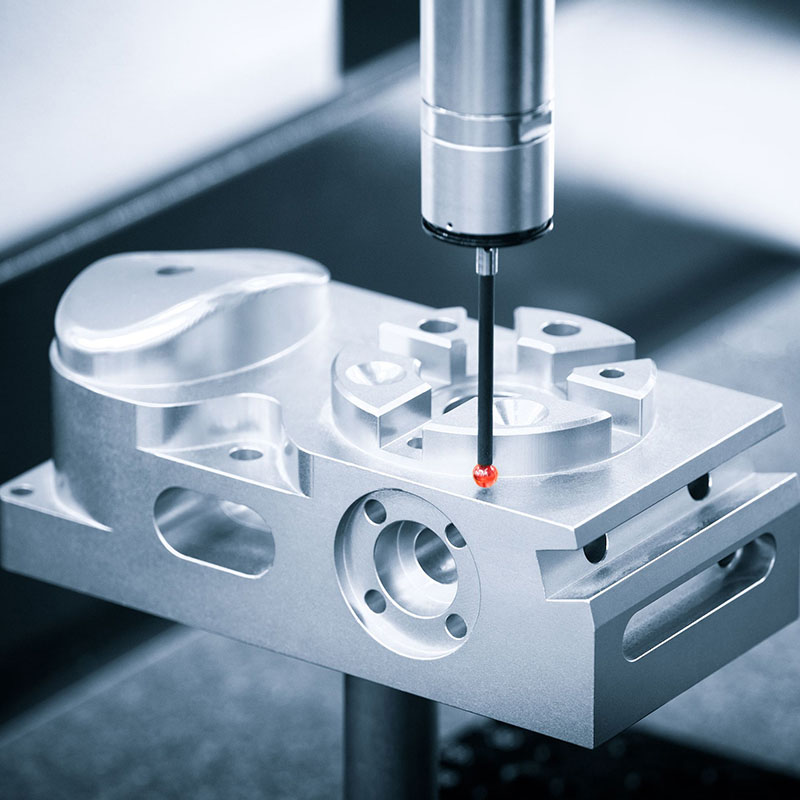

Learn More →Design and production of testing and machining fixtures for computer, communication, and industrial automation fields.

Learn More →Full-cycle automation solutions from concept to deployment, including design, prototyping, volume replication, and on-site testing.

Learn More →

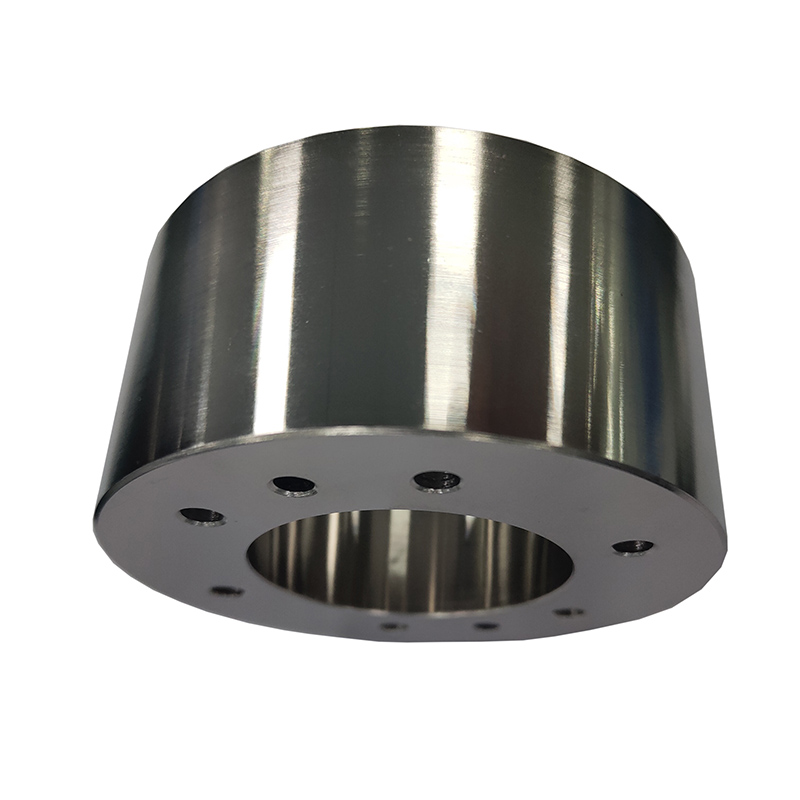

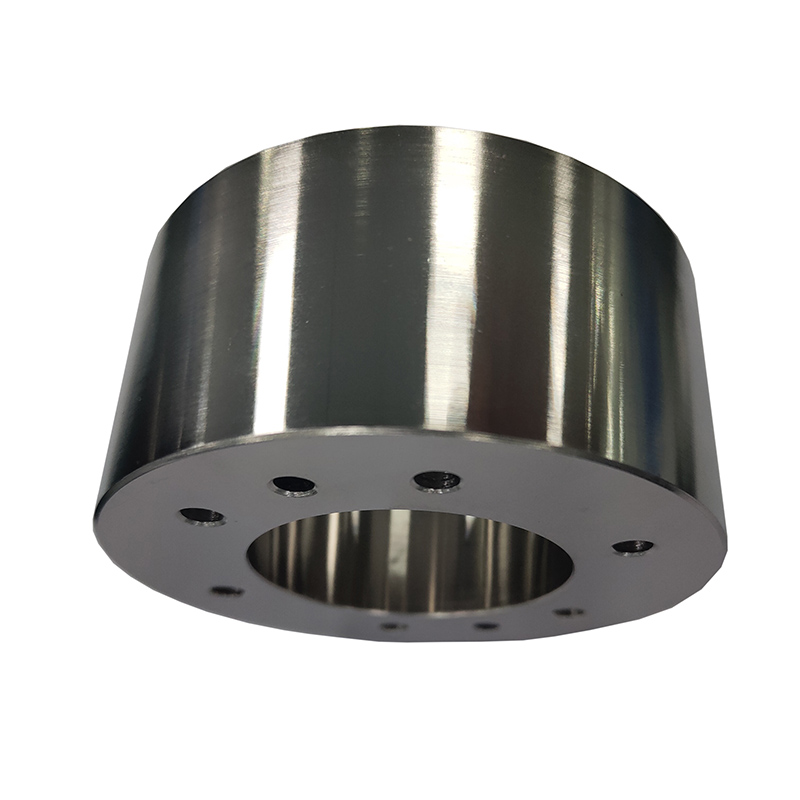

Precision rotary cylinder plate with fine holes, surface flatness up to 0.01mm. Used in measuring machines with zero surface defects.

Special 5083 aluminum polished parts with vertical holes, PCD requirements, and strict tolerance control. Burrs and sharp edges fully removed.

Custom aluminum parts with fine holes, accurate positioning, and flawless surface finish. Strict removal of burrs and sharp edges.

OEM high-precision component for packaging machines. Tolerance ±0.01mm, defect-free surface and scratch-free finish.

Oil-hardened steel parts with electroless nickel plating for food machinery. Enhanced wear and corrosion resistance. Tolerance ±0.01mm.

SCM415 custom machining parts with gas carburizing surface treatment for industrial machines. Improves durability and extends service life.

Designed for computer, communication, and industrial automation fields. Ensures accurate testing and machining alignment.

Fully assembled and functionally tested modules with customer-specified standard parts. Ready for direct integration into your systems.

End-to-end automation solutions from design to volume replication. Improve production efficiency, safety, and energy savings.

We specialize in aluminum (6061, 6082), stainless steel (304, 316), alloy steels (SCM415), and other engineering materials. Surface treatments include electroless nickel plating and gas carburizing.

Lead times vary based on complexity and volume. Prototypes typically take 7–14 days, while production runs are quoted individually. We prioritize speed without compromising quality.

Yes. We provide full module assembly, functional testing, and integration of customer-specified standard parts to deliver ready-to-use components.

Our quality management system meets global industry standards. We maintain strict internal controls and use ERP systems aligned with Industry 4.0 practices.

For inquiries about precision machining, automation solutions, or custom parts, visit our official website to contact the YDZY Tech team directly.

Phone

+86-755-23500669

tthu@szydzy.com.cn

Notice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info