Precision Engineering for Global Innovation

YF ELECTRONICS (HK) CO., LIMITED – Your trusted partner in precision plastic molds, optical grinding, EDM, and high-tolerance metal components since 2011.

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

YF ELECTRONICS (HK) CO., LIMITED – Your trusted partner in precision plastic molds, optical grinding, EDM, and high-tolerance metal components since 2011.

Innovating Precision Manufacturing Since 2011

Founded in 2011 and headquartered in Humen Town, Dongguan City, Guangdong Province, YF ELECTRONICS (HK) CO., LIMITED has grown into a leading provider of precision engineering solutions. Our 1,600+ square meter facility houses a team of 60 skilled professionals, including experienced technicians dedicated to excellence in mold and metal part production.

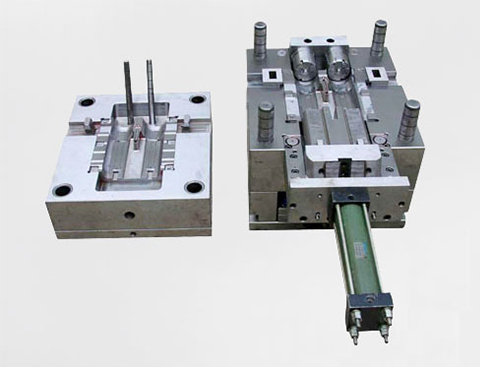

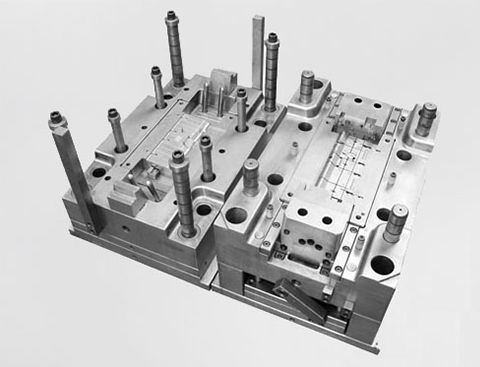

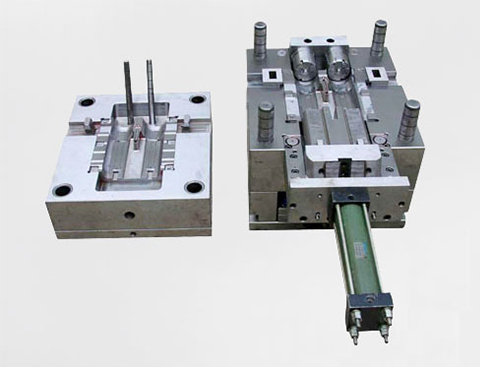

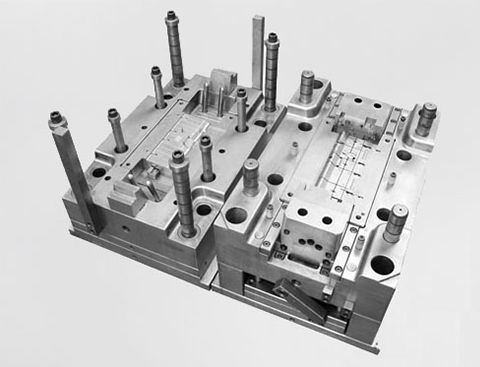

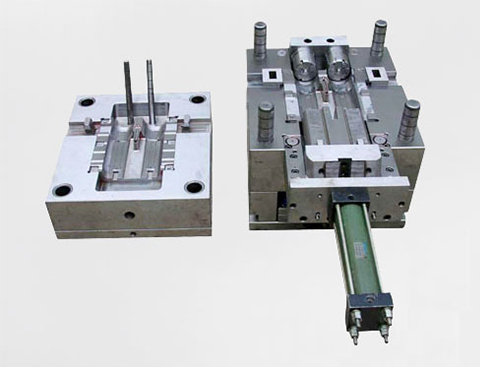

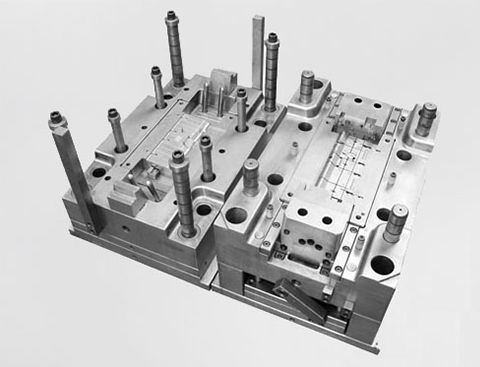

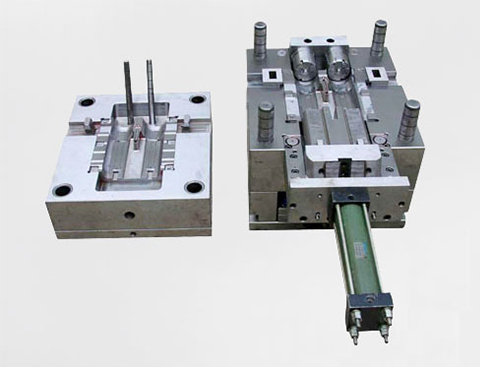

We specialize in manufacturing precision plastic molds, auto parts molds, LED precision molds, and computer connector molds. Equipped with advanced machinery from renowned brands such as MITSUBISHI, Seibu, Sodick, and WAIDA—including mirror discharge machines, optical grinders, and wire-cut EDM systems—we ensure unmatched accuracy and consistency in every component.

Guided by our core values of self-improvement, innovation, integrity, and dedication, we adhere to a strict quality philosophy: "Continuous improvement, pursue quality, technical innovation, seek perfection."

To deliver superior precision engineering services by leveraging cutting-edge technology, continuous innovation, and a customer-first approach. We aim to be the preferred global partner for high-quality mold and metal components.

High-Precision Components for Demanding Industries

Engineered for durability and accuracy in high-volume production environments. Ideal for automotive, electronics, and consumer goods.

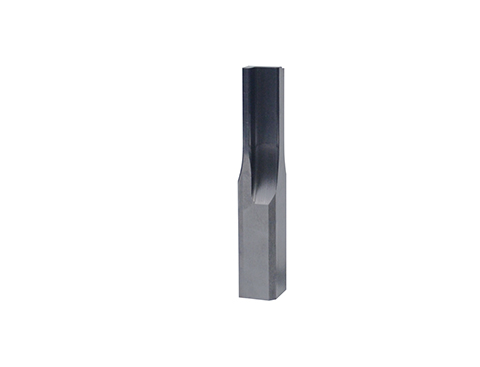

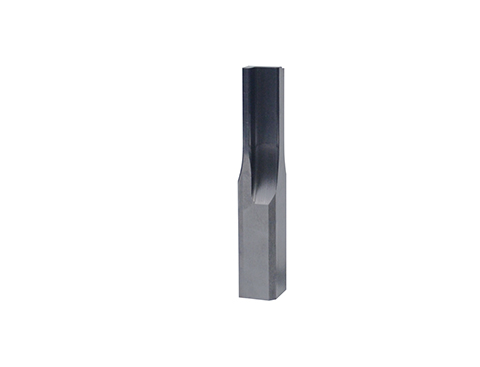

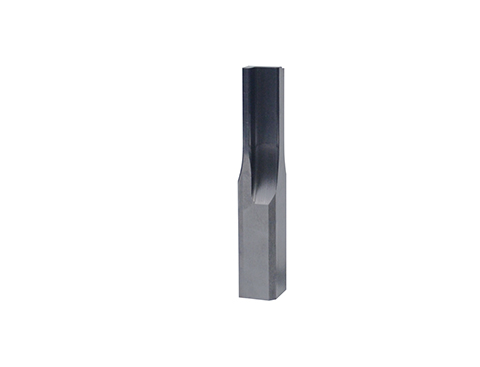

Core pins, ejector sleeves, sliders, and other critical mold elements manufactured with micron-level precision.

Custom-designed stamping dies and press tools for sheet metal forming with long service life and consistent output.

Ultra-precise grinding using optical alignment systems for complex geometries and tight tolerances.

Surface, cylindrical, and centerless grinding services for achieving mirror finishes and dimensional accuracy.

Mirror-finish EDM using Sodick and Mitsubishi machines for intricate cavities and hardened materials.

High-speed wire cutting for complex profiles and tapers with excellent surface integrity.

Guide pillars, bushings, locating rings, and standard mold bases for reliable mold assembly.

Custom CNC-machined parts for industrial, medical, and electronic applications requiring tight tolerances.

Molds for interior trims, connectors, sensors, and lighting systems meeting automotive quality standards.

High-gloss molds for LED lenses, reflectors, and diffusers with precise light control geometry.

High-precision molds for electrical connectors, sockets, and terminal blocks used in electronics and telecom.

Advanced Equipment for Superior Results

Mirror-finish machining with Mitsubishi and Sodick EDM systems for hardened steels and complex shapes.

Sub-micron accuracy using coordinate optical grinders for mold cores, inserts, and precision tools.

Nikon and Trimos CMMs ensure every part meets strict dimensional and geometric specifications.

Efficient workflows and lean manufacturing ensure on-time delivery without compromising quality.

Stay updated with industry trends and company developments

The precision connector involves many aspects, such as product design, technology and quality control. It plays a key role in electronic devices and communication systems.

In order to adapt to the situation, China's mold industry has accelerated the pace of institutional reform and technological innovation, showing strong export potential.

Proper care significantly extends mold life. Regular cleaning, lubrication, and storage prevent corrosion and deformation.

Get in touch for quotes, collaborations, or technical inquiries

UNIT 04, 7/F, BRIGHT WAY TOWER, NO.33 MONG KOK ROAD, KOWLOON, HONGKONG

+852-27027279

Mobile: +86 15818285883 / 13620088258 (Miss Sandy)

sales@yifengelec.com

Notice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info