About Younce Mold

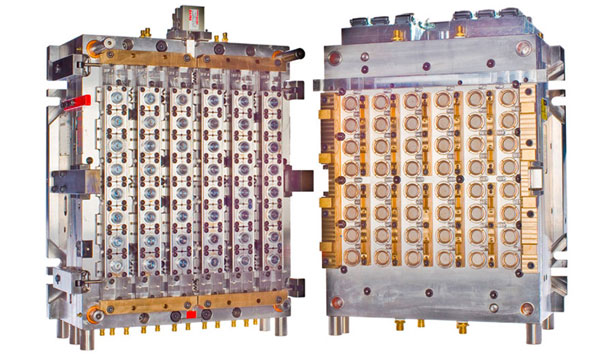

Taizhou Younce Mold Co., Ltd. is a professional manufacturer in the PET packaging industry. We specialize in the design and manufacturing of PET preform molds, cap molds, PET bottle molds, and PET bottle blow machines. Our factory is located in Taizhou Huangyan, China — a world-renowned plastic mold manufacturing base.

Starting as a small mold workshop in 2012 with just two drilling machines, we have grown into a modern facility spanning over 1,500 square meters, equipped with advanced machining centers and staffed by nearly 30 skilled professionals. Our commitment to innovation, quality, and customer satisfaction drives us forward.

- 10+ Years of Industry Experience

- 1500+ sqm Manufacturing Facility

- Full In-House R&D and Production

- Exported to 30+ Countries Worldwide