About YOZEN Mould

A trusted partner in precision mold manufacturing with over 15 years of technical accumulation and 10 years of overseas experience in custom mold development.

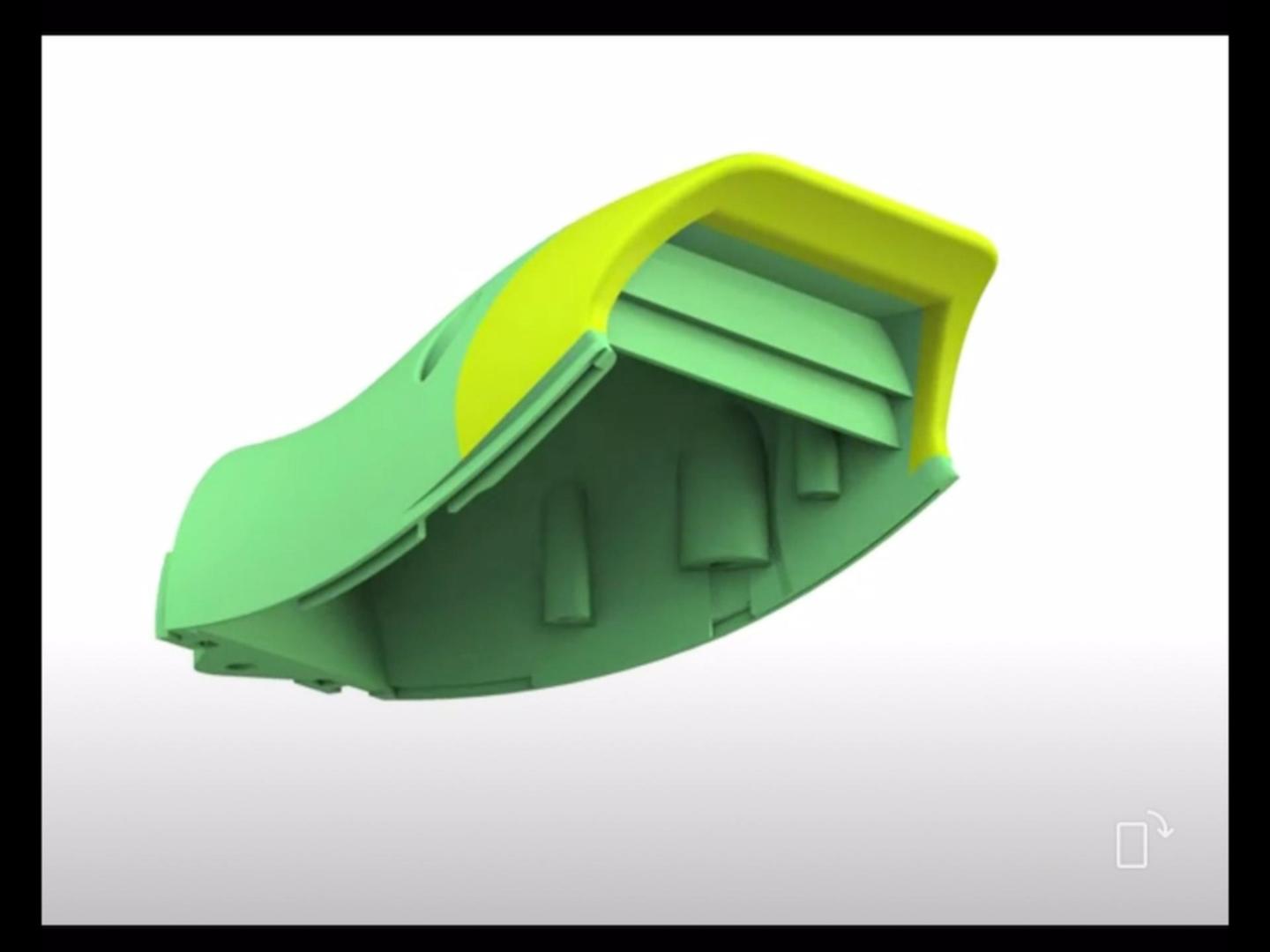

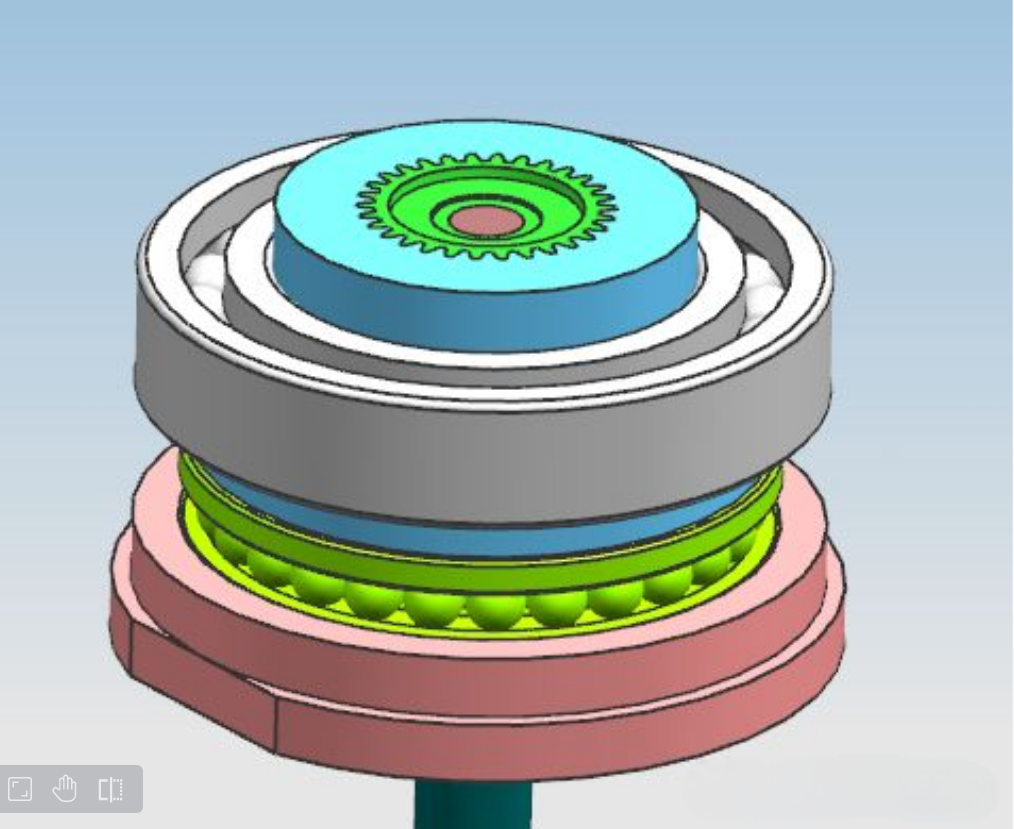

Your Injection Molding Expert

- 15+ Years Experience: Deep expertise in precision manufacturing technology.

- 10+ Years Overseas: Proven track record in international mold customization.

- Focus on Innovation: Specializing in connectors and two-shot molding development.

- One-Stop Service: From mold design to injection molding and final parts.

- Strict Quality Control: Each part undergoes up to 12 inspection procedures.