Our Plastic Mold Portfolio

Explore our range of high-performance plastic molds designed for durability, precision, and efficiency.

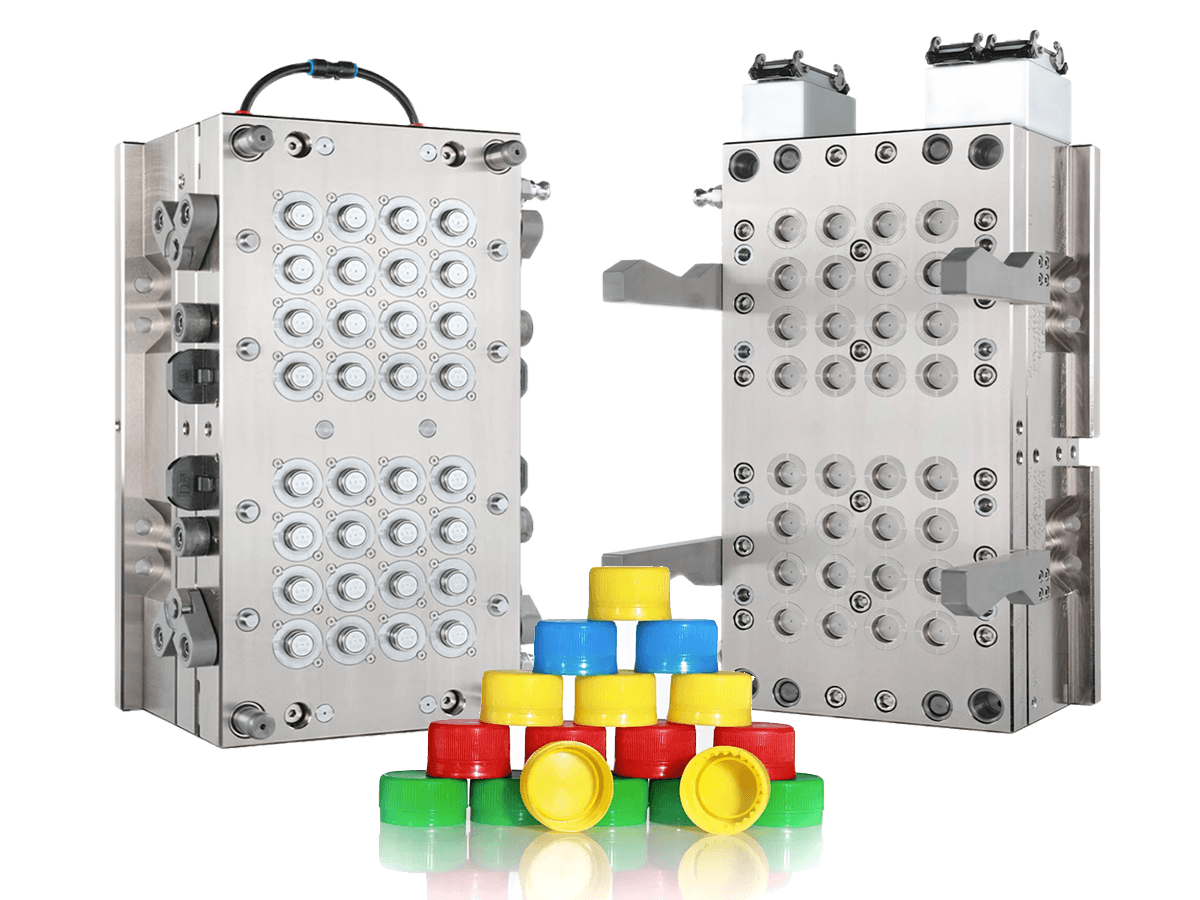

Plastic Cap Mold

High-speed, multi-cavity molds for bottle caps, flip-top closures, and tamper-evident designs. Ideal for food, beverage, and pharmaceutical packaging.

- • Up to 128 cavities

- • Hot runner compatible

- • IML integration

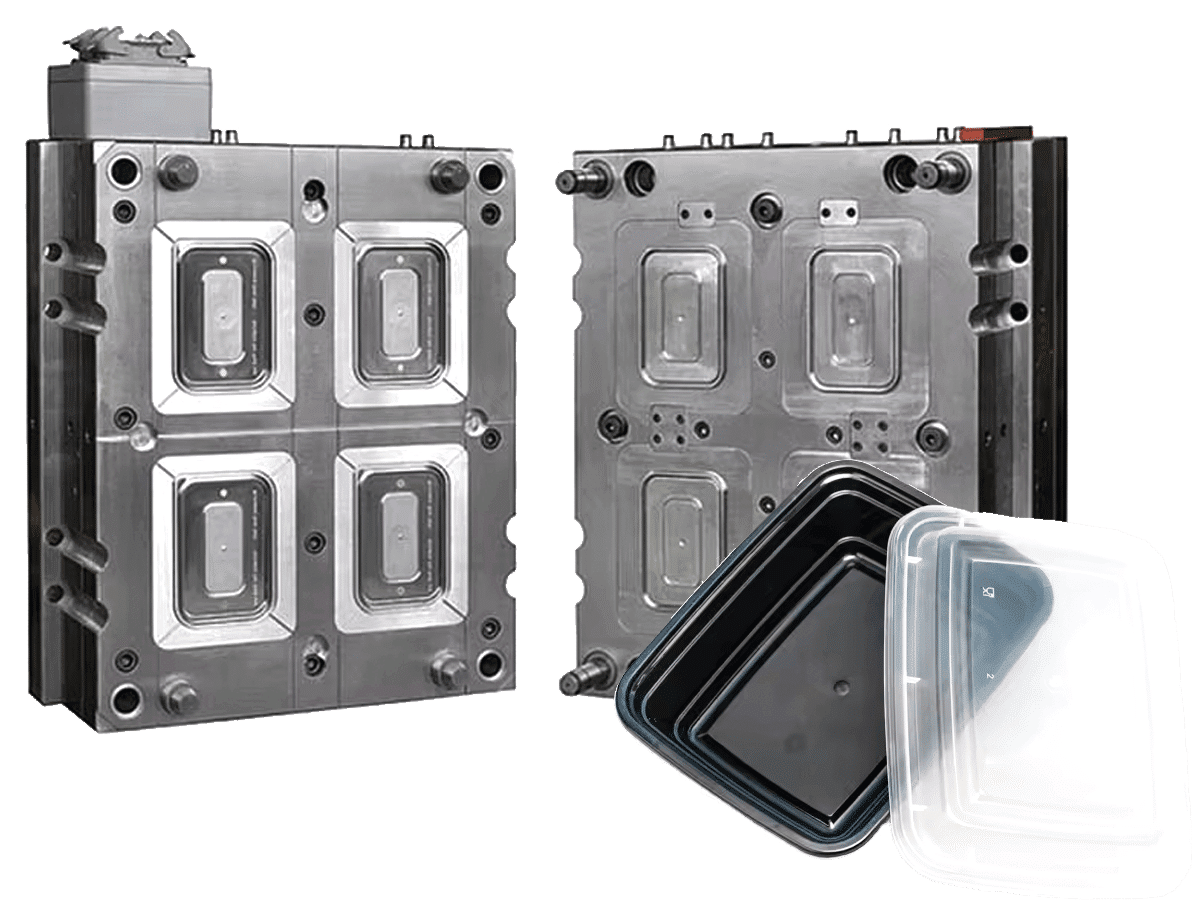

Food Container Mold

Precision molds for microwave-safe, leak-proof containers. Designed for high-volume production with excellent sealing performance.

- • PP, PET, PS compatible

- • Snap-fit lids

- • Stackable design

Cable Tie Mold

High-efficiency molds for nylon cable ties with self-locking mechanisms. Optimized for fast cycle times and minimal flash.

- • PA6/PA66 materials

- • Automatic de-gating

- • High wear resistance

Flip-Top Cap Mold

Integrated hinge and cap molds for dispensing bottles. Features living hinge design and tamper-proof seals.

- • Living hinge technology

- • Two-shot options

- • FDA-compliant materials

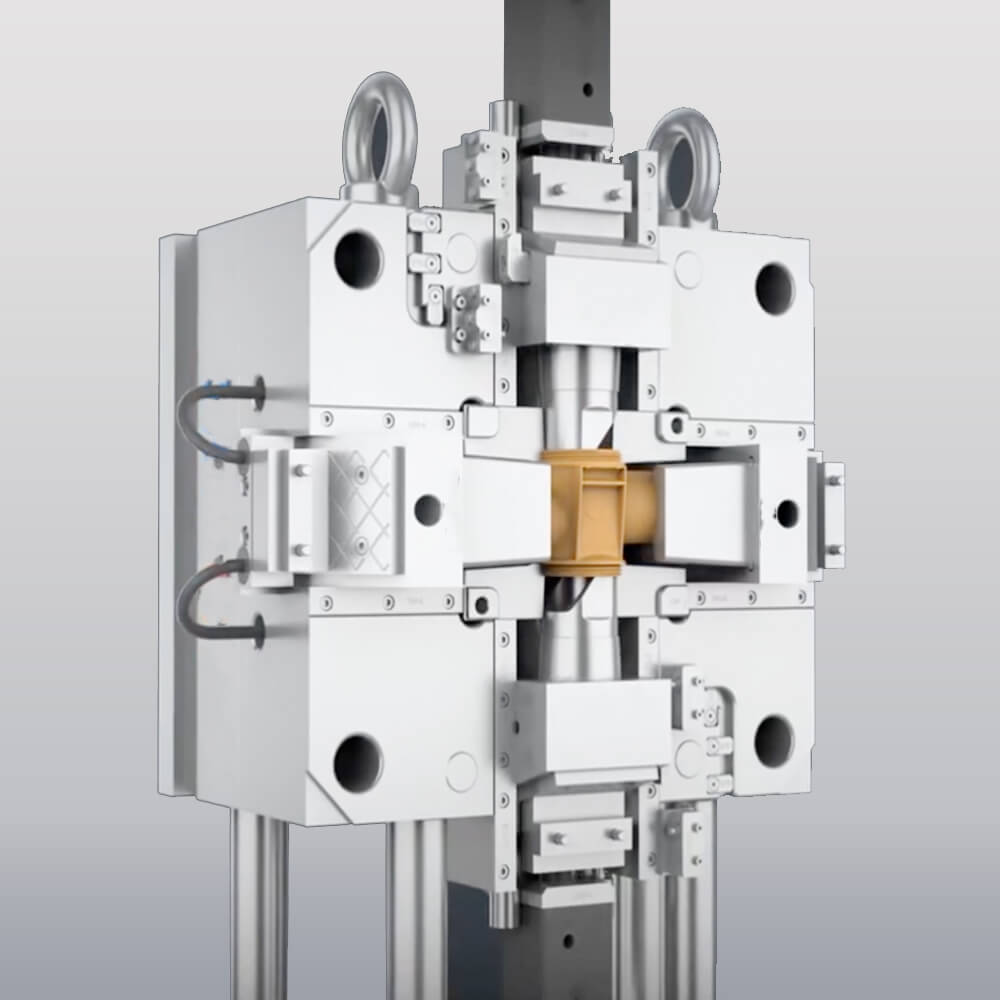

Bucket Mold

Heavy-duty molds for industrial and household buckets. Reinforced walls and ergonomic handle integration.

- • HDPE/PP materials

- • Handle insert molding

- • Stackable design

Crate & Pallet Mold

Robust molds for reusable transport crates and plastic pallets. Engineered for load-bearing and long-term durability.

- • High structural integrity

- • Anti-slip surfaces

- • Nestable & stackable

Basket Mold

Ventilated, lightweight molds for storage and transport baskets. Customizable grid patterns and handle options.

- • Perforated wall design

- • Ergonomic grips

- • UV-stabilized materials

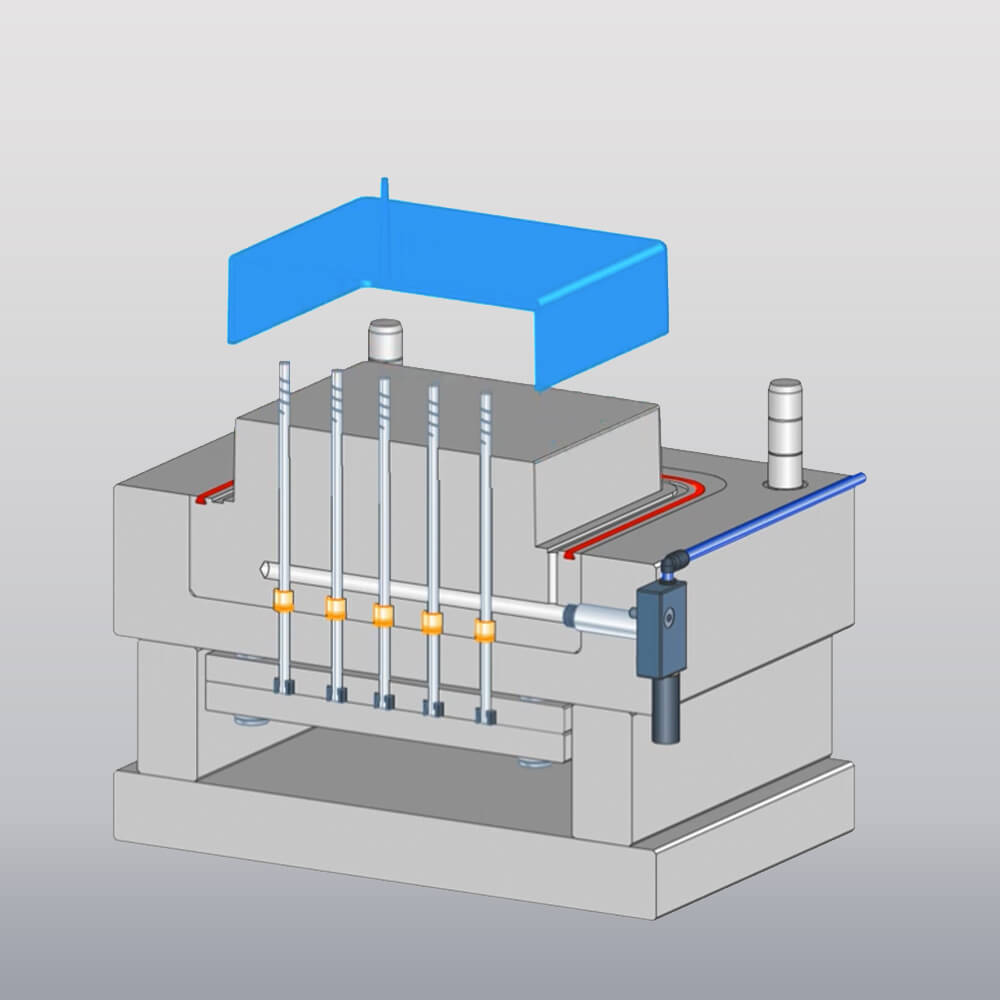

Overmolding & Two-Shot

Multi-material molds for soft-touch grips, seals, and dual-color components. Enhances functionality and aesthetics.

- • TPE over rigid plastics

- • Medical & automotive grade

- • Seamless integration