About YG-PM

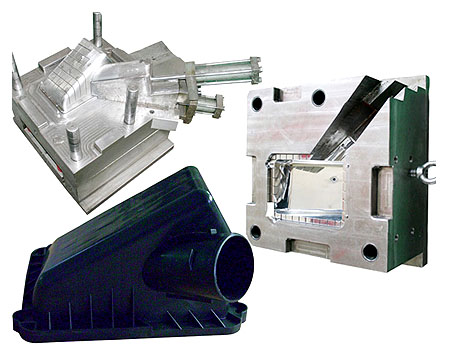

Yuyao Yugao Plastic Mould Co., Ltd. (YG-PM) is a professional plastic mould manufacturer based in Yuyao, Zhejiang, China. With over a decade of experience, we specialize in designing and manufacturing high-precision plastic injection moulds for a wide range of industries.

Our core expertise lies in producing moulds for home appliances such as LCD TV covers, washing machine components, vacuum cleaner parts, air conditioner housings, and more. We also serve the automotive and commodity sectors with reliable, durable, and cost-effective solutions.