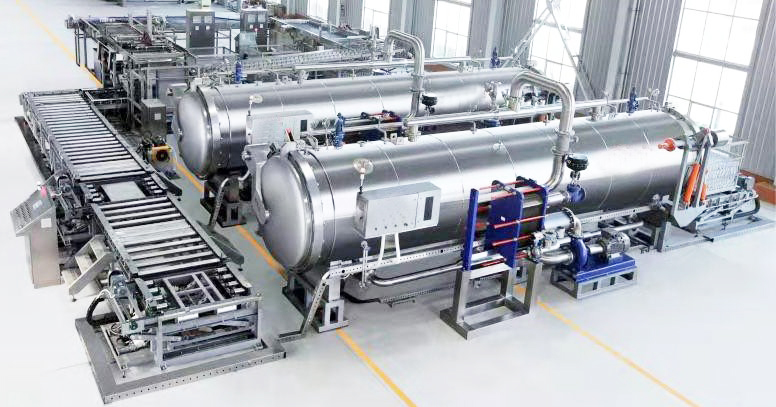

Advanced Food & Pharmaceutical Processing Equipment

Zenith Container Machinery and Engineering Company, established in 1998, delivers integrated turnkey solutions for the food, pet nutrition, poultry, and pharmaceutical industries. With over two decades of expertise, we serve clients globally with cutting-edge machinery and engineering excellence.