About Zhongyang Screw

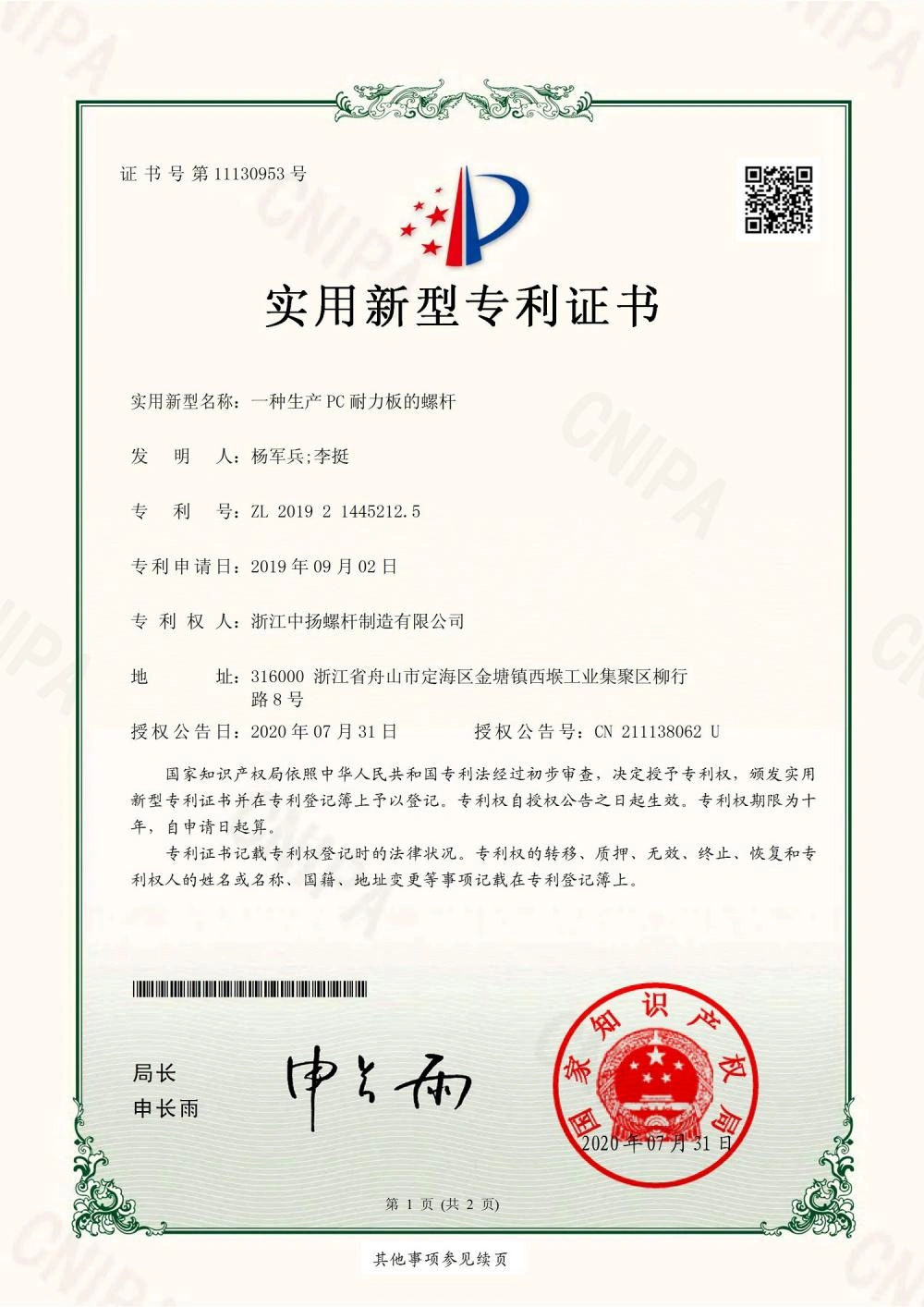

With over 20 years of manufacturing experience, Zhejiang Zhongyang Screw Manufacturing Co., Ltd. has been a leading designer, manufacturer, and supplier of screws, barrels, and assembly parts for plastic and rubber machines since 2006.

Our 50,000㎡ state-of-the-art facility in Zhoushan, Zhejiang, is equipped with over 235 advanced CNC machines, bimetallic casting workshops, nitriding lines, and a full material testing laboratory to ensure the highest quality standards.