Precision Carbide Tools for Modern Industry

Zhuzhou Century Tool Co., Ltd. – Trusted manufacturer of CNC inserts, end mills, PDC/CBN tools, and custom carbide solutions. Serving over 50 countries with unmatched durability and performance.

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

Zhuzhou Century Tool Co., Ltd. – Trusted manufacturer of CNC inserts, end mills, PDC/CBN tools, and custom carbide solutions. Serving over 50 countries with unmatched durability and performance.

As an industry-leading manufacturer, we specialize in producing high-performance mechanical blades, molds, and customized carbide tools. Our advanced manufacturing processes ensure precision, durability, and consistency across all product lines.

Founded in Zhuzhou, China — the heart of tungsten carbide production — we leverage local expertise and global standards to deliver tools that perform under extreme conditions.

From CNC inserts to solid carbide rods, our comprehensive lineup ensures optimal performance across diverse industrial applications.

High-precision CNMG120412-MA with CVD coating for stainless steel, brass, and aluminum. OEM supported.

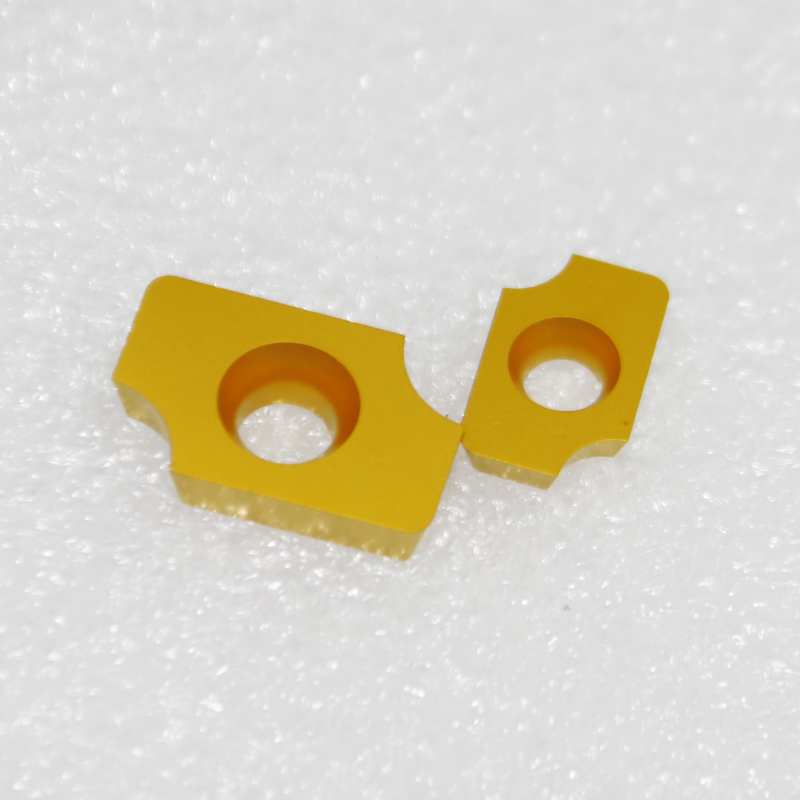

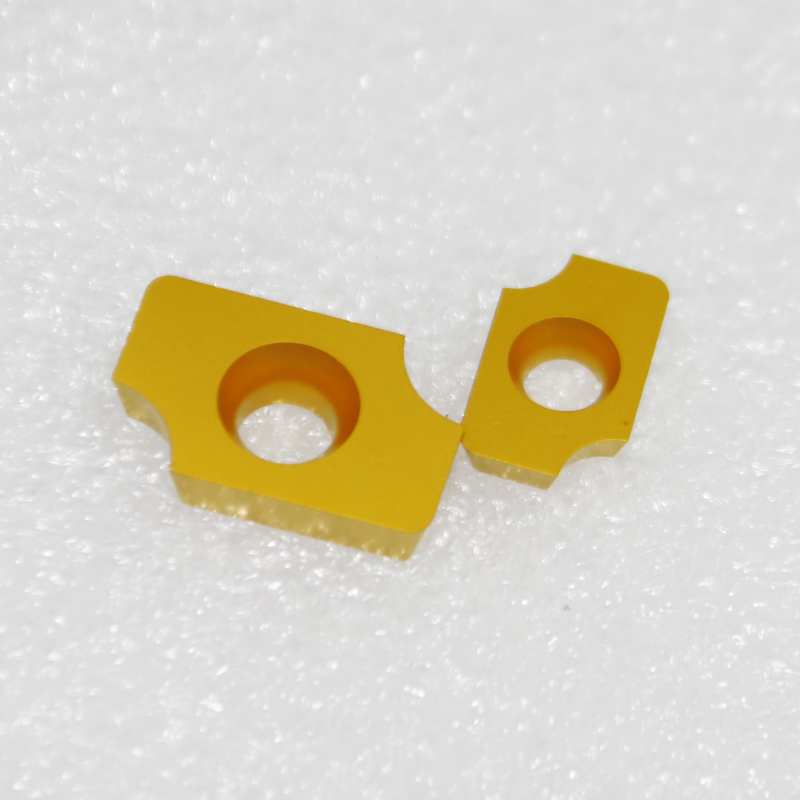

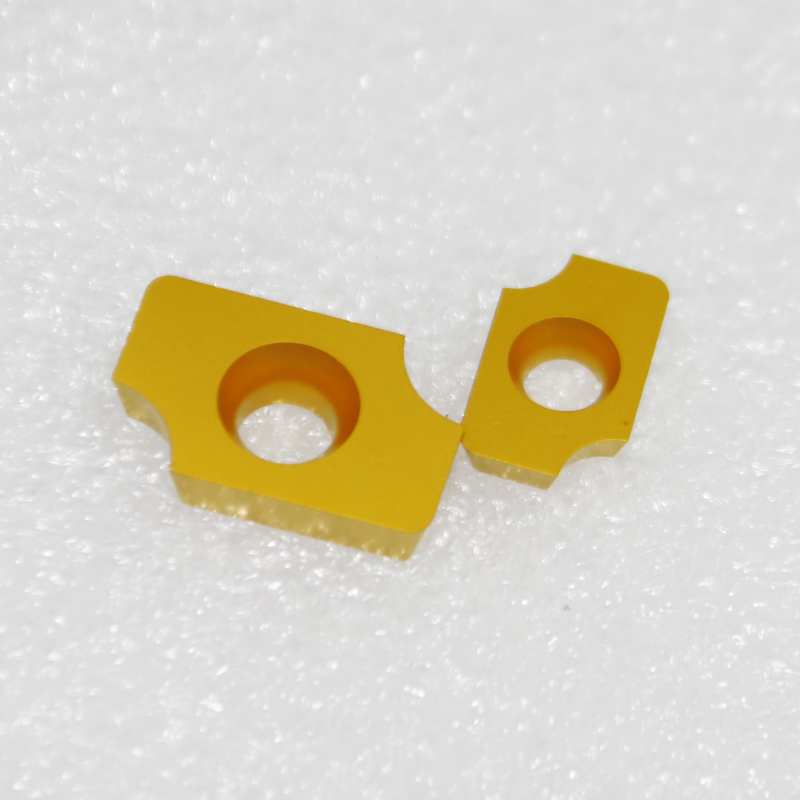

CNC Lathe Spare Part

4-flute square end mill made from tungsten carbide. Ideal for hardened steels up to 65 HRC.

High Hardness Machining

Polycrystalline Diamond (PCD) cutting tool designed for aerospace composites like carbon fiber and glass fiber.

Aerospace GradeIndexable milling insert with MC5020 grade for high-performance CNC machining of ferrous materials.

High Feed Milling

Available in TPMX1403RG, TPMX1704RG, and TPMX2405RG models with TT9030 grade for stable deep hole drilling.

Industrial Drilling

High-density rods in various diameters and lengths for regrinding or custom tool fabrication.

Raw Material Supply

Precision threading tools for internal and external thread cutting on CNC lathes.

Thread Machining

R390 series inserts compatible with R390 milling bars for efficient face milling operations.

Heavy Duty Milling

Polycrystalline Diamond Compact and Cubic Boron Nitride inserts for ultra-hard material machining.

Superhard Materials

Rotary burrs for deburring, shaping, and finishing in metalworking and mold applications.

Finishing Tools

Multi-size step drill bit for screw counterbore applications in sheet metal and aluminum.

Fastener Prep Tool

Customizable cutters for slitting, shearing, and industrial cutting applications.

Industrial CuttingEngineered with precision and tested in real-world conditions, our tools deliver superior performance, longevity, and value.

Advanced CVD and PVD coatings extend tool life even under high heat and pressure.

Optimized geometries for faster feed rates, reduced vibration, and better surface finish.

Tight tolerances and consistent quality ensure reliable performance across batches.

Serving over 50 countries with fast shipping and responsive technical assistance.

Cemented carbide is an alloy made from hard refractory metal compounds (like tungsten carbide) and binder metals (like cobalt) using powder metallurgy. It offers high hardness, wear resistance, and strength at elevated temperatures, making it ideal for cutting tools.

Common types include turning inserts (CNMG, DNMG), milling inserts (XNMU, RNMU), threading inserts, grooving inserts, and drilling inserts. Each is designed for specific machining operations and materials.

Select coatings based on the workpiece material and machining conditions. For example, TiAlN is excellent for high-temperature applications, while AlTiN offers superior oxidation resistance. CVD coatings are thicker and more wear-resistant; PVD coatings are thinner and sharper.

Yes, we provide OEM and ODM services. Our engineering team can design and manufacture custom carbide tools based on your drawings, samples, or specifications.

Have questions about our products or need a custom solution? We're here to help.

Visit Official Website to ContactNotice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info